CNC Machining Services Available at QBH

We have high precision Axis-3,Axis-4,Axis-5 CNC machining centers,professional team and ,advanced management,we can handle all kinds of projects to meed your stands.

CNC Turning Service

CNC Milling Service

CNC Gantry machining service

CNC Machining Capabilities

Feature

Description

- Maximum Part Size: Milled parts up to 80” x 48” x 24” (2,032 x 1,219 x 610 mm). Lathe parts up to 62” (1,575 mm) length and 32” (813 mm) diameter.

- Standard Lead Time:3 working days

- General Tolerances:Tolerances on metals will be held to +/- 0.005" (+/- 0.127 mm) in accordance with ISO 2768 unless otherwise specified. Plastics and composites will be +/- 0.010”.

- Precision Tolerances:QBH can manufacture and inspect to tight tolerances per your drawing specifications including GD&T callouts.

- Minimum part Size:0.020”(0.50 mm). This may vary depending on part geometry and chosen material.

- Standard Lead Time:3 working days

- Threads and Tapped Holes:QBH can accommodate any standard thread size. We can also machine custom threads; these will require a manual quote review.

- Edge Condition:Sharp edges are broken and deburred by default

- Surface Finish:The standard finish is as-machined: 125 Ra or better. Additional finishing options can be specified when getting a quote.

Available CNC Machining Service Materials at QBH

QBH can make use different materials options to meet your demand for CNC machining manufacturing.Here are some common materials types for CNC machining Services.

Plastic CNC Machining Materials at QBH

- Acrylic

- Delrin (Acetal)

- Garolite

- HDPE<br>

- Nylon 6/6

- PC (Polycarbonate)

- PEEK

- PTFE (Teflon)

- PVC

- ULTEM

CNC Machining Design Guidelines

Feature

Description

Internal corner fillets | Design internal corner fillets to be 0.020” – 0.050” greater than a standard drill size for the radii. Follow a drill diameter to depth ratio of 1:6 (1:4 recommended) as a guideline for internal corner radii. |

Floor fillets | Design floor fillets smaller than corner fillets to allow the same tool to clear material from the interior. |

Undercuts | Always design undercuts to standard sizes and away from corners so they are accessible by the cutting tool. |

Tapped/threaded hole depth | Provide tool clearance slightly beyond the tapped hole depth to ensure complete threads.

|

Complexity | Keep the number of small cuts to a minimum to reduce CNC machining costs; only design in the necessary features to balance function with aesthetic. |

Surface Finishes Options for CNC Machining Services

- Variety surface treatment are available for an instant CNC machining services quote.

- Standard (As-Milled)

- Bead Blast

- Tumbled

- Anodized (Type II and Type III)

- Titanium Anodizing

- PTFE Impregnated Hard Anodize

- Chem Film (Chromate Conversion Coating)

- Passivation

- Powder Coating

- Electropolishing

- Electroless Nickel Plating

- Silver Plating

- Gold Plating

- Zinc Plating

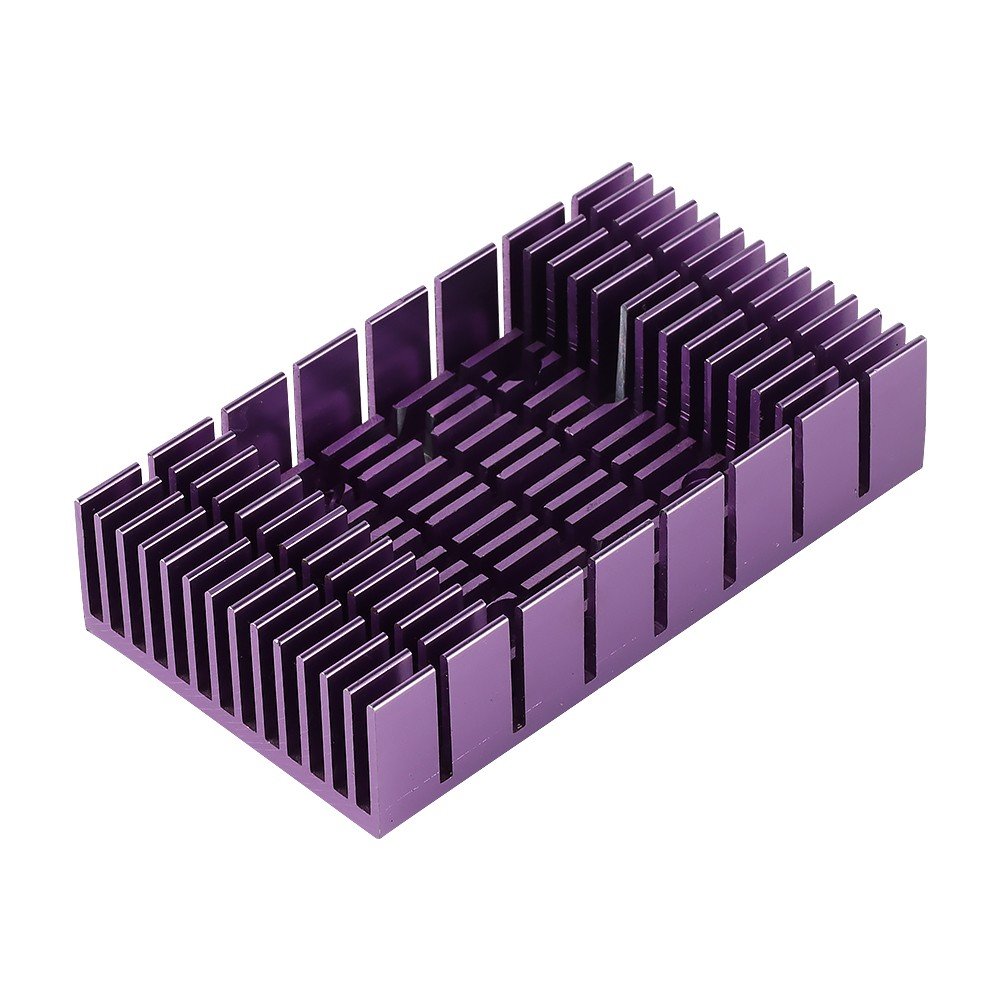

Gallery of CNC Machining Parts

We have manufactured different types CNC machining products for our valued customers.