What is Design for Assembly?

Design for Assembly and design for manufacturing are interchangeably same areas, often referred to by the term DFMA, an abbreviation for Design for Manufacturing and Assembly. The main goal of both these processes is to make CNC machining parts and sheet metal parts cost-effective and better with greater reliability in the least possible time.

Dewhurst and Boothroyd at the University of Rhode Island are the pioneers of ‘The design for Assembly (DFA) methodology. Their methodology is based on designing efficient and highly functional products at a lower cost.

“Design for Assembly” (DFA) mainly focuses on minimizing the parts of a product. The fewer the parts, the less prone the product to errors. Design for Assembly (DFA) also aims to make the assembly operations simpler, easier, and fail-proof and leads to manufacturing the products with improved quality at a reduced cost in a relatively shorter period.

In short, Design for Assembly focuses on minimizing the parts of products and simplifying the design. The product becomes efficient and easy to manufacture and can satisfy the customer and competition.

What are the Objectives/ Goals of DFA?

We have already discussed the basic definition of Design for Assembly. Now we will further look at the objectives of Design for Assembly. Following are some detailed objectives of Design for Assembly:

● Simple products

Design for Assembly (DFA) stresses removing complexities from the design of the products but not compromising the quality of the products and leading to ease of production.

● Reduced Cost

Reduction of cost is the prime objective of Design for Assembly (DFA). Cost-effective CNC machining parts better describe this objective.

● Fewer parts

The product should contain as few parts as possible. On the one hand, these few parts reduce the cost of production and, on the other hand, make the product easier to use.

● Fewer screws

The product should not have a lot of screws and fasteners. Screws and fasteners can add to cost. But it does not mean to avoid screws and fasteners completely. The number of screws and fasteners should keep minimum, and only standard fasteners should use.

● Easy for shipping

There is a need to ship the components all around the world. So the metal parts and components should be easy to pack and ship.

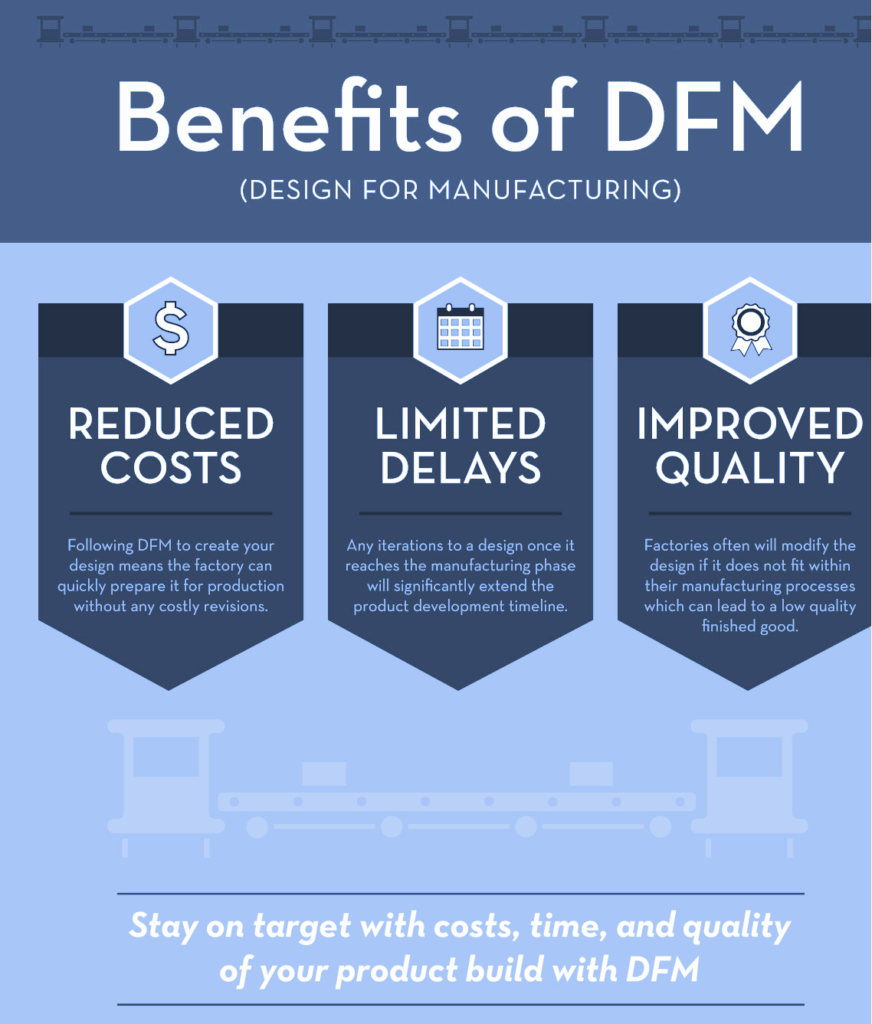

Benefits of Design for Assembly (DFA)

- Design for Assembly makes quick production possible by eliminating prolonged and complicated operations.

- Design for Assembly (DFA) is a method that gives a higher chance of developing high-quality and reliable sheet metal fabrication and products.

- DFA reduces the production equipment, reducing the cost of production and the wastage of material by reducing repeated operations.

- DFA saves equipment capital and also reduces the disassembly process. It can be helpful for easy maintenance and repair.

- DFA reduces labor and increases the profitability of custom CNC machining.

- Design for Assembly (DFA) enables a company the elimination of wastage and provides automation for metal fabrication. It makes manufacturing fast and easy.

Principles of DFA

We examine six principles in DFA or DFM. They are listed below:

- Process

- Design

- Material

- Environment

- Testing

- Usage of Commercially Available Standardized Components & Parts

1. Process

A company’s manufacturing process must be the correct and suitable one. This process can be done by looking at the complexity of a product and how many parts it is made of.

2. Design

Design is of extreme importance. The design stage gives the best opportunity for lowering the costs.

3. Material

The selection of the right material for the product is very important. While selecting the right material, you should consider the following material properties:

- How strong should the material be?

- What should be the optical properties of the material?

- Should the material be resistant to heat or not?

- What should be the color of the material?

- Should the material be a conductor or an insulator?

- Should the material be flammable or not?

4. Environment

The product should be designed according to the environment. All the products and CNC machining parts will go to waste if they cannot withstand the environment they are subjected to.

5. Testing

The product should be according to the quality standards. So, the manufacturer must ensure the quality of the product by testing facilities.

6.Usage of Commercially Available Standardized Components & Parts

It can reduce the amount of fabrication and custom CNC machining in-house and save your money and time. DFA can reduce the assembly cost of manufacturing products and speed up the design process of products. Some examples are springs, sheet metal enclosures, gears, and motors.

DFA (Design for Assembly) Applications

DFA is mostly applicable in those sectors and fields which require efficiency and high-quality product design. So DFA is a basic and important demand both for companies and customers.

The companies such as CNC machining and sheet metal fabrication companies want to reduce labor costs and production costs, so they adopt DFA for product simplification and more reliability. Therefore DFA applications are increasing, ensuring desired results and cost-effective products.

The DFA design greatly impacts the industry and is a widely used method. There are many examples of significant savings through the applications of DFA; like in 1891, Xerox estimated hundreds of million saving through the applications of DFA. So many companies adopted the design for assembly to get great control over the parts manufacturing cost and time.

Difference between DFA, DFM, and DFD

DFA reads as Design for Assembly, DFM is an abbreviation for Design for Manufacturing, and DFD is a short form of Design for Disassembly.

Design for Assembly DFA is a method for cost-effective manufacturing products quickly. It also includes minimizing the part count hence reducing the cost of production this way. Companies should be familiar with Design for Assembly techniques to produce improved and quality products at a relatively lower cost in a shorter period. Although Design for Assembly DFA is a recent method, it was being used by many companies. It was later given the name DFA while these techniques were being employed for a long time.

Design for Manufacturing DFM is an almost similar method to DFA. The main goal of design for manufacturing is cheaper products of improved quality.

DFA and DFM are now also treated as similar terms DFMA. DFMA is a short form of Design for Manufacturing and Assembly. DFMA focuses on reducing the total production cost in a reduced time.

Design for Disassembly focuses on reusing, recycling, and remanufacturing the products, thus saving cost.

Guidelines for DFA

While applying Design for Assembly (DFA) techniques, there are some key considerations. A few are enlisted below:

● Lesser Part Count

DFA stresses minimizing the parts as much as possible for an effective design. Parts should integrate instead of individual parts.

● Minimum Screws and Fasteners

According to DFA, the priority should be to join the parts without using adhesives, screws, or fasteners. But if they are a must, then the following considerations should keep in mind:

- Use as little number and variations of fasteners as possible.

- You should avoid using screws that are too long or too short.

- Try to use the same type of fasteners for an entire product.

- Self-tapping screws should be prioritized.

● Simplified design

If you keep the design as simple as possible, you save your inventory, time, and cost.

● Modular design

The product’s design should be modular, which means the product should have standardized parts. This DFA will help in easy assembly.

● Foolproof

It should not be difficult to take the components of a product apart. And there must be an obvious and easy way to separate the components.

Conclusion

Design for Assembly (DFA) has many benefits for manufacturing companies. From simplifying the design, reducing the time, improving the quality and usefulness of a product, DFA has many benefits for the manufacturers. Design for Assembly DFA is an engineering methodology that makes the product’s design simple, easy, and cost-effective. Design for Assembly DFA saves a lot of time. It also improves the efficiency of assembly.

FAQs

What is the importance of assembly step simplifications?

Simplifying the assembly steps allows you to perform various functions and decreases confusion during assembly. So it is important to simplify assembly parts.

What are the main factors to consider for DFA?

For a successful design for assembly and its applications, there are a lot of factors to consider, such as expertise of engineers, product competitive environments, cost, time, product complexity & intent. These factors can affect the design for assembly, so make sure to check these factors for a good DFA process.

How much time is required for DFA?

Many people want to know how much time is required for DFM and DFA. It depends on its difficulty, customer’s specifications, material, the quality of design, and speed. It is good to consult your product manufacturer to guide you better for everything. You must know that quality should not compromise. So give preference to product quality rather than speed.