Stainless steel is an eroding -resistance of iron, chromium. Or it could be iron alloys with a minimum of 10.5% chromium. Simply, stainless steel is any family of alloy steels, usually, that contain 10 to 30% chromium. This metal of stainless steel would be nikal in some cases or maybe other metals.

Usually, stainless steel could be found in many objects that we are using in our everyday life. Stainless steel plays a vital role in an array of industries including energy transportation, building, research, medicine, food, and logistics.

Chromium content could get by the corrosion resistance of stainless steel. Their chromium oxide is producing on the steel surface, in the form of a stable layer.

The size of the oxide layer is approximately 2 nm_3 nm in thickness and extremely thin. It is passive in nature. Although, stainless steel will have oxidizing properties under specific circumstances. Their uniform corrosion would occur. When it is exposed to an acidic solution of strong sulphuric acid or hydrochloric acid.

DFM DFM stands for design_for_ manufacturing. It is a very significant phenomenon for manufacturing. There are some principles to follow when you are designing sheet metal with. stainless steel.When you are following these principles to design for manufacturing. You could be able to get your desired functionality using stainless steel. It comes on sheet metal from fabrication techniques. In the phenomenon of powder coating, specific stainless steel sheets should be a perfect match. Because stainless steel alloys such as 304 and 301 are not a good match for it. So, stainless steel is not giving a good performance as compared to the matchable stainless steel of 316. Stainless steel of 316 is a good match to perform well in the powder coating process.

Additionally, stainless steel has many significant properties. Such as, there are more than 60 categories of stainless steel. Chromium gives unique properties to standard steel. It also works against rust. Commonly, stainless steel is a non-magnetic material. But in some types of stainless steel, there are magnetic properties. These properties depend on the microstructure of a specific type of stainless steel. Stainless steel also has the significant property of being recyclable.

The interesting fact about stainless steel is it may expand and contracts.

Stainless steel is very significant for nuclear power and aerospace industries. The reason is that there is a high-temperature oxidation resistance of stainless steel.

Comparatively, it is a higher resistance temperature than many other metals. When the temperature varies stainless steel shows interesting properties of expansion and contractions. Due to this property, experts should be very careful while creating steel frames for buildings. For example, during the summer, the Eiffel Tower is almost 984 feet tall. Moreover, in the contrast season of cold, the Tower is 6 inches shorter than 984 feet.

Mechanical properties of stainless steel

Although stainless steel encompasses, huge range of materials. But its mechanical properties are quite diverse. Generally, it has tensile strength, hardness, toughness, creep resistance, and fatigue resistance properties.

Stainless steel shows specific properties in different situations which are applying to it. Such as it’s cold working to elevate work hardening and avoid tearing or cracking.

Stainless steel is also so hot working at specific conditions of 1149_1260°c. Its purpose is a cool rapidly and enjoys maximum corrosion resistance.

Electric and magnetic properties of stainless steel

Stainless steel has electric and magnetic properties such as stainless steel is a relatively poor conductor of electricity. Additionally, the conductivity of 18 wt % cr .8 wt %. Ni stainless steel at 20°c is 1.45 × 106 s/m compare to 5.96 × 107 s/m for pure copper.

Commonly, stainless steel is classified into four main categories. This classification is occurring depends on their crystal structure, Ferritic, martensitic, austenitic, and duplex.

Difference stainless steels are classified as magnetic and nonmagnetic. Such as Ferritic, martensitic, and duplex are included in magnetic. And austenitic is non_ magnetic.

Many types of stainless steel show melting properties in an electric arc or basic oxygen furnaces. Then it could be defined in another steelmaking vessel that has the property of low carbon content.

In the process of argon_ oxygen decarburization, and they’re a mixture of Oxygen and argon gas is injected into the steel which is in liquid form.

Stainless steel usage in industries

Usually, stainless steel plays a vital role in industries. Typically, stainless steel applications include aircraft, diary, and food processing industries.

There are different types of formulations of stainless steel. Each of them has specific properties and unique characteristics to use and handle with precautions. For example, 304 stainless steel is a type of stainless steel that is of higher ultimate tensile strength. Stainless steel is beneficial in the formation of engine and exhaust components, gear components, and superstructures joints. It reduces parts rejection and provides floor space. Therefore, stainless steel plays a key role in the aircraft industry.

Stainless steel is beneficial in automated manufacturing robots.

In the performance and price, all stainless steel for sheet metals is different. The alloy makeup is different in all stainless steel sheets. If you want to choose stainless steel material for your industry use or for any other purpose. Because you should choose the right alloy for your purpose. It will save your cost and gives the best performance by its application.

There are many applications of stainless steel. As it is used to make durable refrigerators and washing machines. It also has capital good applications for example transportation.

In the food manufacturing process stainless steel play a basic role.

Because it is useful In manufacturing the range of materials to stalk convey and process the food products. the food factories, two types of stainless steel are common. These types are 304 stainless steel and 316 stainless steel. Both have different and specific properties and qualities.

Although, stainless steel has a strong quality of resistance. But it is not stain-proof completely. As we know that stainless steel has many types. Each type has a different and specific quality. The resistance quality of stainless steel will depend on makeup which is present specific in each type.

Ranges in thickness.

Stainless steel huge range of thicknesses. It could be quite thin. It could reach 1/4 inch in thickness. The type of stainless steel that is is larger than 1 /4 in thickness, will be a plate. The gauge is useful for measuring the thickness of stainless steel sheets. If that use number would be higher the sheet would be thinner.

Before choosing the right alloy for your application. You should make some research by yourself because it is very important to know about different alloy situations. Misuse may be harmful or can create critical situations. With these precautions, you can achieve your dream of functionality from stainless steel sheets. Your safety must be your priority. If you don’t have enough knowledge about it, don’t use it and consult a specialist.

Stainless steel is present with many configurations

while stainless steel sheets metal comes with many configurations. Each of the configuration-specific advantages and disadvantages to use it. Manufacturers of metal fabrications main offer different grades, finishes, and sizes. But there is a notable difference in specific types of stainless steel sheets.

Many types include:

- Martensitic

- 200 series Austenitic

- Ferritic

- 300 series Austenitic

- Martensitic

- Duplex

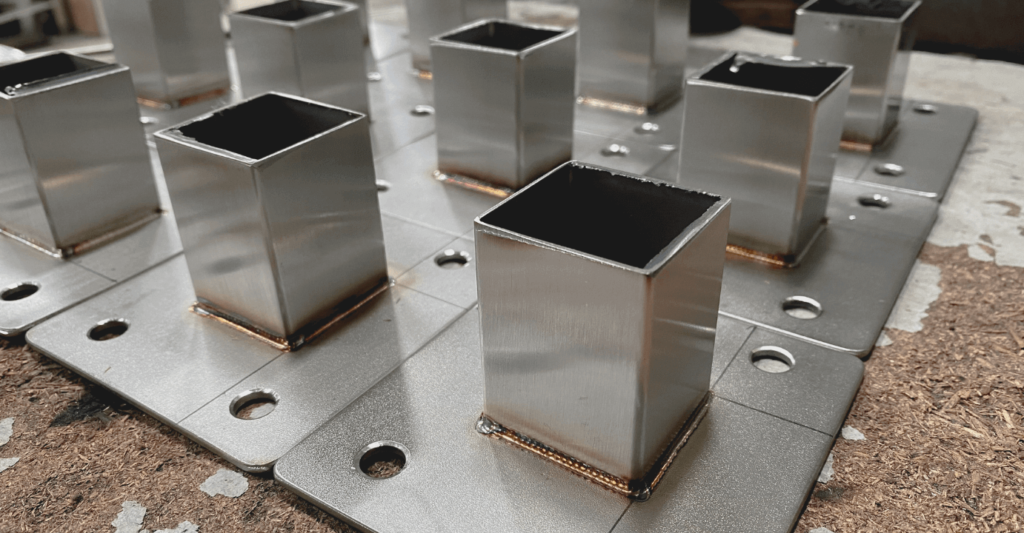

Stainless steel play a role in welding

Usually, stainless steel has its application for welding purposes. It plays a very beneficial role in welding. But, stainless steel sheet metal when using in welding its thickness and heat distribution creates difficulties in welding.

Bending

Stainless steel plays a significant role in bending. The thinner sheet is easy to bend. It could be easily bending by using a hand. But when we are bending harder sheets then we should have a bending tool that bands stainless steel.

Cutting

For cutting purposes, stainless steel is significant to cut Hi-Tech lasers. Along with, metal snips, jigsaws, hacksaws, and other band saws.

Other industries with basic use of stainless steel

Stainless steel plays a vital role in industries. It is responsible to perform different duties in industries according to their type and use.

There are some industries in which stainless steel presents to do the best performance.

- Energy

- Diary

- Aircraft

- Architecture

- Food processing

- Construction

- Heavy industries which are responsible to manufacture heavy goods and materials in bulk

- Automotive

It also plays a beneficial role in the dairy industry. As a material of the industries is made of stainless steel, which provides excellent reliability with long-term quality. Stainless steel is a sign to use in the diary because it prevents chemical bacteriological and organoleptic neutrality to the food products. It also has the ability to do cleaning or washing easily. So hygiene and appearance of the product are guaranteed.

Therefore, stainless steel sheet metal is specific material. This material provides choice to a number of industries for its application. It has significant properties of reliable, durable, and resistant properties.

If you have any questions or confusion. You are free to plz ask in the comment box. And leave a reply. We will get back to you as soon as possible.