The Importance of Sheet Metal Gauge for Sheet Metal Fabrications

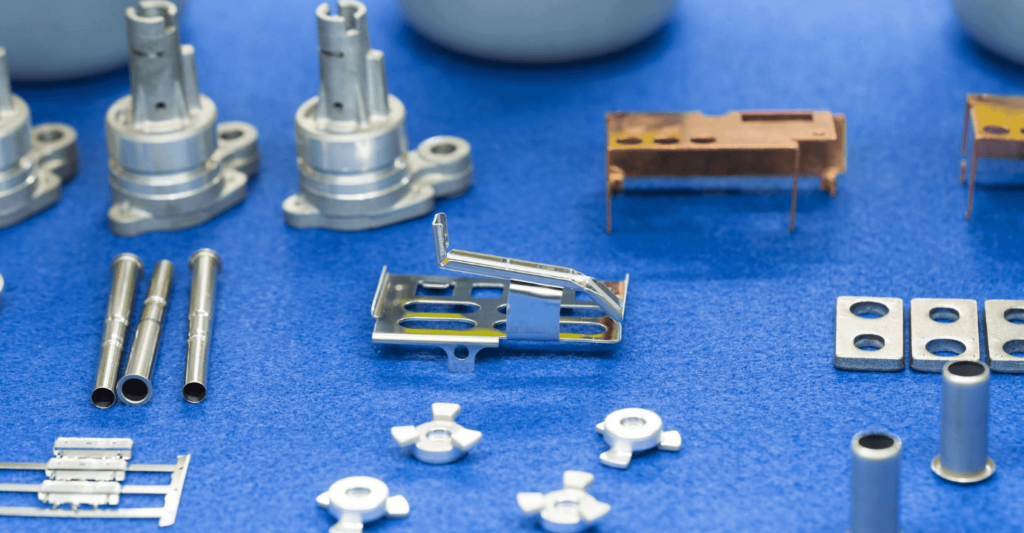

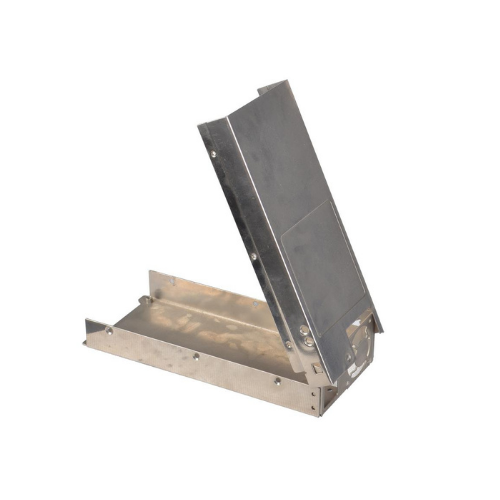

Sheet metal fabrication is creating different objects by using metal sheets. It may look simple process, but in reality, it is a very complicated and detailed process. The metal sheets are flexible metal sheeting. It means that you can cut, design, and give them desired shapes. Sheet metals are used mainly in:

- Building materials

- Computers

- Architectural materials

- Dumpsters

- Structural materials

- The automotive industry

A wide range of sheet metal thicknesses and the metal sheets’ sizes can use in industries. The thickness of the sheet metal varies from object to object. The thin metal sheets can term leaf or foil, while the thick metal sheets term plate. By gauge, you can measure the thickness of the sheet metal. If the gauge number is smaller, the sheet metal is thicker.

Similarly, the more significant gauge number shows thin sheet metal. Usually, the gauge numbers used range from 30 to 7. The range of the gauge number varies with the type of material used. The sheet metal gauge is considered very important for metal sheet fabrication. Let’s find the importance of the sheet metal gauge for sheet metal fabrication.

Importance of Sheet Metal Gauge

As we know, there is a great importance of sheet metal gauge in sheet metal fabrication. This importance is because choosing the wrong sheet metal gauge can lead to an undesired final object because of varying thickness. It can be proving damaging for your reputation, and your customers can dissatisfy.

Hence to design the object with the desired thickness, it is compulsory to choose the required sheet metal gauge. For a successful business project, selecting the right and suitable design and desired thickness for your metal parts is critical.

Sheet metal gauges have much importance in various sectors. Some prominent factors of the importance of the sheet metal gauge are as follow:

1- Economic

Economically it is crucial to choose the accurate sheet metal gauge with a thin or thick metal sheet. Each object can design with a definite sheet metal thickness. Some objects can design with thick sheet metal, while others can design with thin sheet metals. If a thing that requires a thin metal sheet to design can create with a thick metal sheet, then the object’s design and shape are destroyed. The thing needs to design again, which requires more cost.

The same is the case with creating an object that requires a thick metal sheet with a thin metal sheet. So, the sheet metal gauge is crucial because it will determine your requirements and the exact thickness needed to design the desired object. Otherwise, your budget can disturb harshly if the sheet gauge is not chosen wisely. In this way, the thing with the same thickness can design and makes it cost-effective.

2- Deformation and a Structural Problem

The sheet metal gauge also plays a vital role in reducing the deforming and structural problems in sheet metal fabrication. The objects can design with a very thin metal sheet in most cases. If a little more force can apply to such objects, they may undergo structural changes and deform easily. Such things cannot maintain their shape for a long time and hence lose their functions and cannot use for longer. By sheet metal gauge, you can choose metal with enough thickness to prevent the deformation and the structural changes in the sheet metal fabrication, making the object more reliable.

3- Durability

The object’s durability is also greatly dependent on the sheet metal gauge. The sheet metal gauge determines the exact thickness of sheet metal while designing an object to design perfectly. It helps efficiently work the thing for a longer and thus makes it durable.

4- Flexibility

The metal sheet gauge is compulsory in choosing the metal sheet for an object that requires flexibility. If you have to design a thing that requires certain different curves or that may need flexibility, then you must choose a thin sheet metal. This selection is due to the reason that you can easily add curves in thin sheet metal. But if you go for thick sheet metal, it can be a more complex process, and you may not get the desired results. Thus choosing a thin sheet metal with a gauge can give the required flexibility to your designed object.

Deciding the Best Sheet Metal Gauge for the Sheet Metal Fabrication

It is also compulsory to decide the best sheet metal gauge for sheet metal fabrication. If you don’t choose the correct sheet metal gauge, it may lead to the failure of your object design.

So for the proper functioning and the efficiency of your object, you must choose the appropriate sheet metal gauge. By following simple ideas/steps, you can decide the best sheet metal gauge for your project sheet metal manufacturing.

Cost is the main factor when deciding a suitable sheet metal gauge for sheet metal fabrication. The sheet metals made of thick material can find at a much higher cost than those containing lighter components. Thus they are more expensive. Before selecting sheet metal, you must consider which purpose you will choose the sheet metal. In this way, the best sheet metal gauge can help you save costs.

When deciding on a sheet metal gauge, you must have a complete idea of what kind of object you will design. If you have to create a thing that needs rigidity, you must go for the lower gauge sheet materials. If you choose a lower gauge, the object you design will be rigid and thicker. If you have to design a thing that should be flexible and need different curves, then you must go for the high gauge material. Thus, the high gauge material can create flexibility and lack rigidity.

Certain environmental factors may also affect your designed object. If you have to keep your thing in an open environment, select the lower gauge material. The lower gauge material will protect your designed object from harsh environmental conditions such as high temperature, high pressure, or extreme weather. If you have to protect your created object from harsh conditions by keeping the thing indoors, you must select high gauge material.

The right choice of the sheet metal gauge greatly affects the efficiency of the designed object. If you do not choose the suitable gauge sheet metal for your thing, your created object will not function properly. An object made with an accurate thickness of sheet metal will operate efficiently. So, for the efficient working of the thing, you must consider a sheet metal with the required thickness.

It would help consider other factors when deciding on a perfect sheet metal gauge. These factors include:

- Hardness

- Ductility

- Maximum temperature

- Tensile strength

- Surface finish

- Malleability

- The cost of the sheet metal fabrications

Without these, you cannot select a suitable sheet metal gauge for your sheet metal fabrication.

FAQs

1- For what purpose a sheet metal gauge can use?

A sheet metal gauge may use to determine the sheet metal’s thickness. It tells us the appropriate thickness of the sheet or whether the sheet metal is thick or thin. To determine the exact thickness of the sheet metal in millimeters or inches, you can also use a gauge conversion chart. By choosing the exact thickness of the metal sheet with the help of a gauge, you can design an efficient object.

2- What are the types of sheet metal materials?

You can use a wide range of materials for sheet metal fabrications. Following are the main types of sheet metal materials.

- Stainless steel

- Aluminum

- Brass

- Mild steel sheet

- Galvanized steel

- Corrugated sheet metal

- Alloy steel

3- Why a sheet metal gauge can use for measuring the thickness of sheet metal?

The thickness of a metal sheet can also measure without a sheet metal gauge, but you will not get accurate measurements. So to get the exact thickness, the sheet metal gauge is commonly used.

4- What are the advantages and disadvantages of sheet metal materials?

The followings are the advantages of sheet metal materials.

Advantages

- Sheet metals are durable and malleable.

- They can be easily replaced, fixed, or repaired.

- They are easily transportable and sustainable.

- They are considered environmentally friendly and are recycled.

Disadvantages

They are mostly expensive and may take time to manufacture products.

Conclusion

Metal sheets can use throughout the world for manufacturing various objects. The sheet metal gauge is compulsory for sheet metal fabrication as it specifies the thickness of the sheet metal. Without proper consistency, the thing cannot work efficiently and loses its durability.

So, to retain efficient working and durability, specifying the thickness with the help of a sheet metal gauge is essential. The gauge also aids in maintaining the shape of sheet metal, thus protecting it from deformation. The gauge also affects certain factors such as the sheet metals’ cost, scenario, and efficiency. So, one should be careful while deciding the best sheet metal for their construction project.