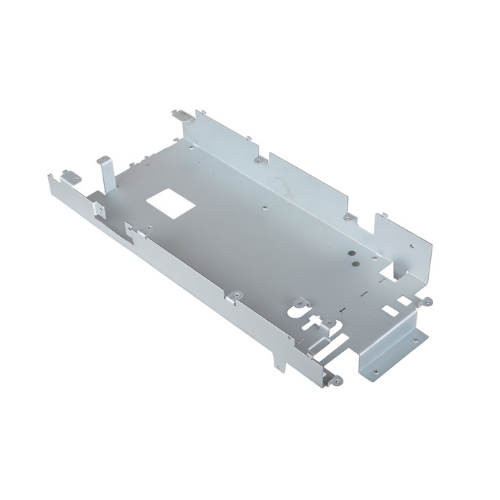

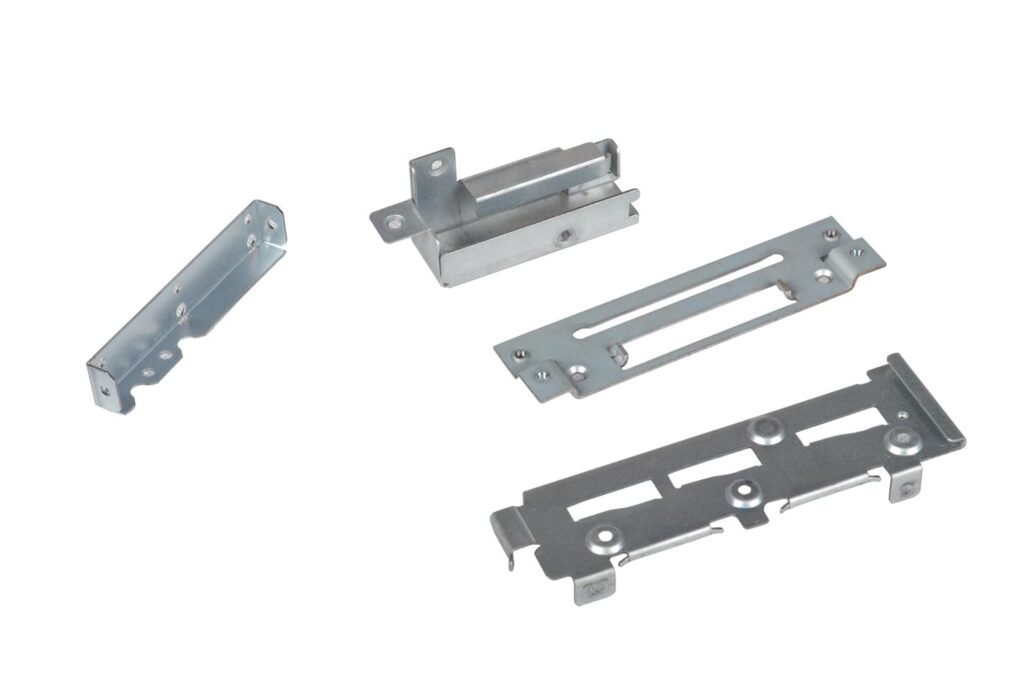

Metal Stamping Service

Professional Supplier for Metal Stamping

QBH Technology provides different different kinds of Metal Stamping service. Metal stamping uses a stamping press to shape flat sheet metal, also called stamping blanks. It is a complex process that the tool and die surface use various techniques to work the metal, depending on the products you need.

QBH is a leading manufacturer that can provide metal stamping services to deliver components for industries in automotive, aerospace, medical, and other markets.As global markets evolve, there is an escalated need for quickly-produced large quantities of complex parts.

Progressive

With progressive stamping, we move strip metal through a progressive stamping press, where it passes from one station to the next. Each station performs a specific function, including punching, bending, and cutting the metal.

Often, progressive stamping requires multiple machines, especially when a project involves complex parts. Progressive stamping offers the advantages of a quick turnaround and creating repeated, uniform pieces. It also has the lowest labor cost of each stamping type.

Fourslide

Fourslide stamping uses four tools, with each one bending the metal into the desired shape simultaneously. Fourslide stamping simplifies the creation of complex parts. While it doesn’t create pieces with as much uniformity as progressive stamping, it makes changing or adjusting the design easier when a project requires many parts with different bends.

Deep Draw

Deep drawing is a technique where we use a punch to feed a blank into a die. It works best for projects where a customer needs products of different diameters, often in the automotive or aerospace industries. Deep drawing uses fewer raw materials than other stamping processes. It also works well for producing less complicated pieces at high volume.

Industries all over the world use metal stamping to create intricate components for machinery. Since the process is quite affordable, many companies choose this process to create durable parts quickly. The Federal Group USA offers metal stamping services for many companies across all industries. We’ll walk you through the process of meeting your metal stamping needs, so you get the parts you need when you need them.

You can find stamped metal in almost any industry. You probably have stamped metal in virtually all rooms of your home.

We use sheet metal stamping to create products for industries like:

- Automotive

- Agricultural Parts

- Aerospace

- Electronics

- Home appliances

- Lighting

- Medical

- Military

- Telecommunications

Metal stamping has a long list of available materials for custom prototypes and manufacturing parts, from hard metals like stainless steel and titanium, to soft metals such as aluminum, copper, brass, all the way to plastics including ABS, PC, PA, etc.

A wide range of materials can undergo sheet metal production. Some most commonly used materials that can be beneficial are listed below:

- Aluminium:Grade 6061,Grade 6082,Grade 7075,Grade 6061,Grade 5083

- Brass:C36000

- Mild Steel:Grade 1018,Grade 1045,Grade A36

- Alloy Steel:Grade 4140,Grade 4340

- Stainless Steel:Grade 304, Grade 316,Grade Duplex 2205,Grade 303,Grade 17-4

- Tool Steel:Grade D2,Grade A2

- ABS

- Nylon

- Polycarbonate(PC)

- POM(Delrin)

- PTFE(Teflon)

- HDPE

- PEEK

The surface finish available for sheet metal fabrication depends on which material and what is the part used for. The finishing options RapidDirect provide for sheet metal services are listed below:

Anodizing

- Materials:Aluminum

- Color:Clear, black, grey, red, blue, gold.

- Texture:Smooth, matte finish.

- Thickness:1.8 μm to 25 μm (0.00007″)

- Materials:ABS, Aluminum, Brass, Stainless Steel, Steel

- Colors:n/a

- Texture:Matte

- Standards:Sa1, Sa2, Sa2.5, Sa3

- Applications:Cosmetic parts

Brushing

- Materials:ABS, Aluminum, Brass, Stainless Steel, SteelColors:n/aTexture:satinStandards:Sa1, Sa2, Sa2.5, Sa3Applications:Cosmetic parts

Powder Coating

- Materials:Aluminum, Stainless Steel, SteelColors:Black, any RAL code or Pantone number.Texture:Gloss or semi-glossApplications:Vehicle parts, household appliances, aluminum extrusions

Electroplating

- Materials:Aluminum, Steel, Stainless Steel

- Plate type:Tin, Nickel, Electroless Nickel

- Texture:Smooth, glossy finish

- Applications:Electrical connections, jewelry, radiation shields

- Subtypes:Galvanizing, nickel plating, tin plating, passivation

Polishing

- Materials :Aluminum, Brass, Stainless Steel, Steel

- Colors:n/a

- Texture:Glossy

- Types:Mechanical polishing, chemical polishing

- Applications :Lenses, jewelry, sealing parts

Tell us your needs and requirements now, we can provide the best solution for you.

Best quality with best service

Share This Products, Choose Your Platform!