Environmental protection has always been a cause of concern, ever since the industrial revolution. Whether due to excess energy consumption or toxic waste products, factories have become one of the biggest environmental polluters.

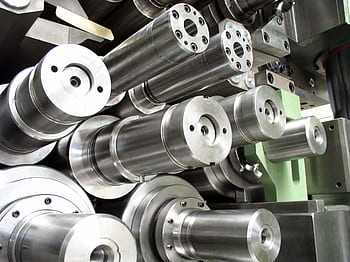

Factories perform various operations, but the one we want to discuss today is Steel Machining. Steel is a popular metal due to its relatively low cost, high strength, and excellent alloy selection.

This article breaks down the various environmental impacts of steel machining and discusses possible solutions to this problem.

What is Steel Machining?

Machining is a subcategory of subtractive manufacturing, which removes material from the workpiece until desired final shape and size is achieved. Steel is one of the most popular metals for machining; It has good corrosion resistance, high strength, durability, decent thermal resistance, and it can be reasonably cheap. Additionally, you can modify all of these properties by using alloys.

For example, Carbon Steel 1045 is used for machining high-strength parts. And Stainless Steel 303 is used for machining parts with lower strength but higher corrosion resistance.

What are the Environmental Impacts of Steel Machining?

The most significant environmental impact of steel machining is energy cost, and it’s mostly related to poor machining practices. For easy understanding, we will break down the environmental impact of steel machining into Two Sections.

1. Machining Environmental Impacts

Let’s start with the material cost; machining involves using a large steel blank and slowly cutting it down to shape. Larger steel blanks are easier to machine, allowing operator mistakes to be easily fixed.

But, using excess material is has both a direct and indirect environmental impact.

Direct Environmental Impact

The direct environmental impact comes in excess machining times and excess material use. The former results in increased energy consumption and later increased material waste.

Indirect Environmental Impact

Machining companies don’t refine their steel; instead, they order the raw steel billets from a steel factory. Steel billets are refined from iron ore at the factory and then shipped to machining companies. Refinement and shipping both have an attached energy cost. If companies are inefficiently using this material, they will have to order more steel billets, which will cost even more energy.

2. Waste Management Environmental Impacts

The second type of environmental impact associated with steel machining is waste management. Steel machining results in waste chips being formed; they are thin, sharp, long, and covered in coolant, requiring protective gloves to handle them.

These waste chips are generally referred to as swarf, and this swarf can be as much as half the volume of the steel blank. Steel is a non-renewable resource; there is a limited amount of steel on this planet. Of course, the more material we waste, the worse it is for the environment.

How can we Reduce the Environmental Impacts of Steel Machining?

So far, we have only discussed the negative impact of steel machining on the environment. But now, we will shift to something positive and discuss the solutions for environmental protection.

Honestly, there are simple steps that can drastically reduce the environmental impact of steel machining.

1. Better Machining Practices

This one is difficult to explain because there isn’t just one type of machining. So we will discuss the improvements to general machining practices a manufacturer can take.

- By selecting the right-sized steel blank. Oversized blanks are easier to machine but waste more material.

- By selecting a suitable steel alloy. Some alloys require less energy to machine than others.

- By ordering custom-sized billets. Billets come in various cross-sections; order the most suitable size for your production.

2. Using Efficient CNC Machining

CNC (Computer Numerical Controlled) machining controls the cutting tool feed using a computer system. In short, CNC automates the machining process.

As a manufacturer, you can significantly improve the energy efficiency of steel machining by using CNC machines, which are more accurate precise and result in minimal product defects. CNC machining results in significantly lower machine times, thus saving time and energy.

Also, since CNC machining is exact, you don’t need to use oversized steel blanks.

3. Recycling Steel Swarf

Finally, the most meaningful method of reducing the environmental impact of steel machining is “Recycling”. Depending on the part, the material loss can range from 10 percent to 90 percent. Recycling this material is an absolute necessity for protecting the environment.

Recycling steel is a simple process if a bit time-consuming. Following are the basic steps of steel recycling.

- The steel swarf is cleaned for any dirt or coolant.

- The cleaned steel swarf is further chopped into fine steel particles.

- These steel particles are then headed to a high-temperature furnace for melting.

- All remaining impurities will float to the surface after melting.

- The pure molten steel can be poured into molds to make steel billets.

Environmental Impact of Steel Recycling

Steel is a high-strength metal, thus requiring lots of heat to melt and recycle. Even though recycling is supposed to be better for the environment, it uses an enormous amount of energy.

You may be thinking that steel recycling is a very environmentally unfriendly process. BUT only if you look at steel recycling in a bubble. Taking a step back and looking at the iron mining industry reveals the bigger picture.

The energy cost of mining iron ores and refining them into steel is significantly higher. Studies show recycled steel costs between 50-75% less energy than iron ore refinement.

Overall, by considering the above steps to reduce the hazardous effect of steel machining, the process can become sustainable and suitable for environmental protection.

Conclusion

Now that you have gone through this entire article, we hope you understand steel machining better. Steel is a vital manufacturing material, and machining steel consumes a lot of energy. Poor machining practices and lack of recycling have a heavy impact on the environment.

But this also means by simply adopting CNC machining and recycling waste steel chips; we can negate most of the harmful environmental impact. Environmental protection and steel machining can co-exist; it just requires initiative from companies to shift to environmentally friendly practices.

If you are looking for steel machining services and want environmentally efficient manufacturing. Please contact with QBH Technology.

We offer CNC machining, laser cutting, and high-quality welding services. Additionally, we accept custom orders of server racks and cabinets and general electronic enclosures.