Introduction

Brass is an important copper alloy with many useful properties, high machinability being one of them. It is being used widely in all kinds of CNC machining manufacturing machines, particularly in CNC machining. Currently brass is CNC machined to make many types of components such as wires, brass gears, prototyping, 3D modeling, musical instruments, furniture and much more.

This article discusses the use of brass in CNC machining, different alloys, their properties, and finally, the advantages. Let’s get into it.

Brass – An Overview

Brass is basically an alloy of copper and zinc including minute proportions of other elements like silicon, arsenic, manganese, aluminum, and magnesium. The percentages of copper and zinc are varied to make different alloys of brasses with different appearances and properties.

Bronze is often confused with brass due to its similar appearance, but bronze is an alloy of copper and tin and bears different properties.

All brasses are highly ductile and malleable. They can be easily shaped, formed, and cut into complex shapes and parts. Musical instruments and jewelry are examples of how brass can adopt any shape with ease.

Due to its golden and shiny appearance, brass is used in many decorative elements, household utensils, and jewelry. Its high thermal and electrical conductivity makes it prevalent in applications such as wiring and bullet shells. Combined with high corrosion resistance and low friction, it is widely used in the making of gears, doorknobs, hinges, valves, and other fittings.

In addition, brass offers a unique anti-bacterial property that lets it kill certain types of bacteria when they come in contact. This is paving way for brass to be used in marine applications such as ship hulls.

Can You CNC Machine Brass?

Yes. Second to aluminum, brass is highly prevalent in CNC machining due to its excellent machinability. Compared to aluminum that sticks to the machine during machining, brass chips do not stick. The tool retains its sharpness and efficiency in brass machining.

Due to their good hot and cold formability, these alloys are extensively in industries for making screw machine parts, gears, fasteners, marine hardware and components, pump shafts, etc.

Brass is 100% recyclable. This makes it highly cost-effective and energy-efficient in CNC machining.

What Are the Benefits of CNC Machining Brass?

The main component of brass is copper. So, many of the benefits of copper are directly inherited by brass. Copper is a softer metal with excellent shear resistance. Brass maintains most of this shear resistance and gains high tensile strength from alloying with other metals.

Following are a few benefits for CNC machining brass,

Efficient Machining

The high tensile and shear properties of brass make it excel at high-speed machining. High-speed machining can result,

- The workpiece heating up

- Large chips forming

- Distorting or cracking in rare cases.

Brass is a softer metal that is easier to cut. Thus, it is resistant to all of the issues mentioned above. Machining at high speeds shortens the cycle for parts manufacturing. Making the overall machining process incredibly time-efficient. Moreover, brass machining has no negative impact on the machine itself. The tools do not get damaged due to sticky chips. On the other hand, chips fly away making the cleaning easier and fast.

Precise Machining

Brass has good impact resistance and thus higher deformation resistance. These resistances allow for brass to maintain its dimensional accuracy after machining.

So, if your manufacturing requirements involve strict tolerances such as applications of gears, valves and bullet shells, brass is a great option.

Brass Alloys

Brass isn’t limited to a single use-case. Brass is an alloy with a wide range of grades commercially available. Corrosion resistance, strength, formability all can differ based on the brass grade.

For example, Brass C35300 has excellent corrosion resistance. But Brass C86200 has excellent strength.

The versatility of these grades further adds to the benefits of Brass machining.

Brass Tooling

The tools required for a CNC machine depend on the material of the workpiece. Harder workpieces need stronger cutting tools. As brass is easier to cut, its tool compatibility is high.

Easier to cut metals also cause far less wear and tear to the tool. Thus, a single tool can machine for a long time without being replaced.

Tool and tool maintenance costs are reduced when you’re CNC machining brass.

Cost-Effective Machining

Brass machining is more cost-effective because of all the previously discussed benefits. You will spend less time matching brass. End up with precise dimensions, and save a lot on tooling costs.

What Are the Drawbacks of CNC Machining Brass?

Brass has little to few drawbacks when concerned with machining. The majority of the shortcomings of brass are related to the material itself.

Oxidation

Brass can oxidize easily, causing a blackish coloring in the metal. Most brass products need to be lacquered after machining to prevent oxidation. But with time, the lacquer will wear away.

Thus, you will need to lacquer every part you make using brass. Additional time is spent applying lacquer, reducing the initial efficiency of brass machining.

Corrosion

Most brass alloys are fairly corrosion-resistant. But since the base metal for brass is copper, it is susceptible to water damage. Corrosion can make storing brass a hassle.

Season Cracking

One another disadvantage of brass is the occurrence of stress corrosion cracking. It is highly susceptible to cracking in an atmosphere having ammonia.

What Is Unleaded Brass?

Despite the naming, unleaded brass does not mean zero lead content. Unleaded brass must contain less than 0.25% lead. This is opposed to the 8% typically used in brass alloys.

Unleaded brass is defined in the “Reduction of Lead in Drinking Water Act”. Though this is an American bill, manufacturers of brass alloys use this to label their products as “unleaded” or “lead-free”.

Is It Easy to CNC Machine Brass?

Yes, brass is easy to machine, especially when compared to other metals. Brass is often alloyed with lead, a much softer metal. Since lead also has a lower friction coefficient, it produces less heat when machining. Allowing brass to be easily machined at high speeds.

Leaded Brass is very beginner-friendly. Since it has less tool wear, brass can be forgiving if the feed is incorrect. Novice operators may want to try machining brass before difficult metals like steel.

But if the lead is responsible for easy machining of brass. Then what about unleaded brass?

No, Unleaded brass is not easy to machine. By decreasing the lead in brass, it becomes harder. Which will result in an increased friction coefficient for the material. More friction means more heat and more tool wear. Unleaded brass alloys also produce longer and string-like chips.

Machining unleaded brass requires coolant for friction heating. And constant monitoring and management of metal chips.

Brass itself is still an excellent choice for machining. But depending upon the application, unleaded brass may be required. So, you must take extra precautions when selecting the right brass alloy for machining.

Uses of Brass

Brass can be used for several applications because it possesses both mechanical properties as well as an attractive appearance. Brass applications can be divided into two categories,

Aesthetic – Polished brass has a bright and shiny finish. It also bears a striking resemblance to gold. Making it desirable for decorative applications.

Functional – Brass has good corrosion resistance and a low friction coefficient. Making brass an excellent metal for technical applications.

Following are a few common use cases for brass,

- Musical Instruments – Trumpet, horn, tuba, etc.

- Plumbing Equipment – Pipe, faucet, fittings, etc.

- Ammunition Casings

- Precision Instruments – Watches, barometers, locks, etc.

- Decorative Furnishing – Handles, Trims, rivets, etc.

- Underwater Applications – Radiators, Coating for ship hulls, etc.

Popular Alloys of Brass for CNC machining

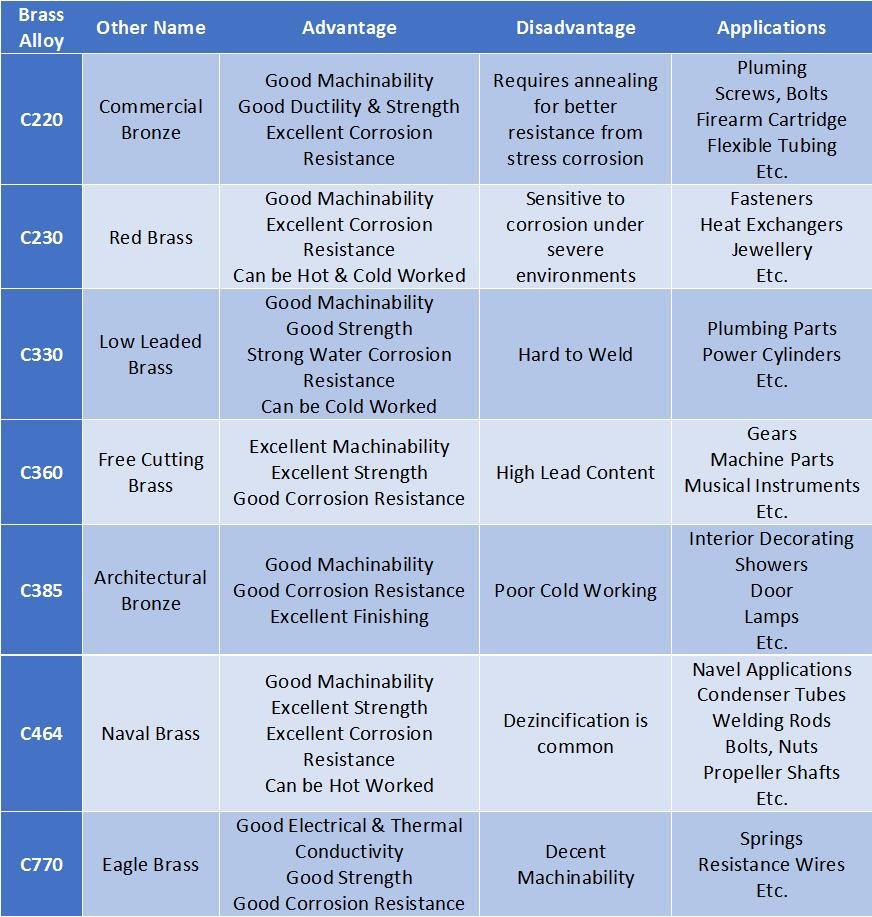

Brass alloys used in CNC machining are all application-based. When selecting a suitable brass alloy, you should consider your desired properties.

Following are a few popular brass alloys commonly used in CNC machining.

Table 1 Brass Alloys

Some brass alloys are also called “Bronze” in the industrial sector. These are brass alloys that are given names based on their appearance.

Final Words

We have everything you need to know about the CNC machining of brass, its uses, the difficulties to address, and its advantages.

Now that you know the benefits of Brass in CNC machining let us carry out your brass jobs with high precision and unmatched efficiency. Take your brass projects a notch higher using our expertise in machining all materials. QBH has a team of CNC experts having a lot of experience in brass CNC machining.

Other than brass, we can perform CNC machining on many different metals including stainless steel and aluminum. We can perform high precision CNC axial milling (3,4 or 5 axis milling), sheet metal fabrication, and offer postproduction services. QBH is always willing to discuss your projects, brainstorm solutions, and help you decide what is best for your projects. Call us anytime!