2D drawings first become prominent during the 1800s. And until a few decades ago they were the only method of conveying product designs to manufacturers. With the advent of 3D modeling, you may think that 2D drawings have become obsolete, but that is not the case. Many industries still use 2D drawings alongside 3D models and some exclusively rely on them.

In this article, we explain the reasons for 2D drawings’ popularity and its importance in the manufacturing sector.

What are 2D Drawings?

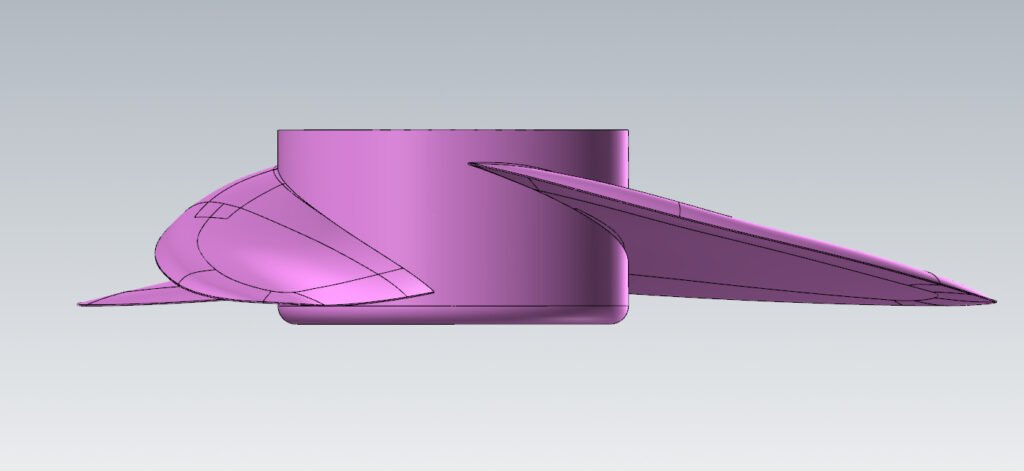

A 2D Drawing is a two-dimensional flat representation of the six sides of a specimen (3D model). It shows all the details and dimensions of the specimen while following standards for drawing views. In the past 2D drawings were drawn by hand on large pieces of paper, but now it is mostly done on CAD (computer-aided design) software.

Types of 2D Drawings

There are two main types of 2D drawing which are known by their angles of projection. An angle of projection consists of three main elements, the object (specimen), the observer, and the projection paper. The difference between types of drawing depends upon the relative positions of the three elements.

First Angle Projection

In this system of drawing projection, the specimen is firmly placed between the observer and the drawing canvas (paper).

Third Angle Projection:

In a 3rd Angle Projection setup, the canvas (paper) is firmly placed between the observer and the specimen. This is the more commonly used projection system.

Importance of 2D Drawings for Manufacturers

Multiple factors affect the operational flow of the production line. Design and modeling are the first of these key factors. 2D drawings bring several advantages to the production process, that ensure the importance of this design technique.

Following are a few elements of 2D drawings that cement their importance in the manufacturing space.

Adaptability

Complex geometries require additional machining processes. In order to reduce time and cost, it is important to introduce adoptable production skills to ensure good productivity and cost-effectiveness.

2D drawings are compatible with both automatic CNC machining and manual machining practices.

Tolerance stacking

Each manufactured part has some associated tolerance. When assembled into a complete section, individual tolerances add up to a significant level.

In this aspect, 2D drawing ensures the lowest tolerances level, as the tolerance for each section can be drawn separately.

Flexibility

This is important to achieve better production efficiency and conditions. In terms of Drawing and designing products, it is essential to include these factors/changes in the production cycle.

2D drawings are simple and easy to change, modify, and edit. This also helps with prototyping as minor changes to each iteration become easier and quicker.

Error Identification and Reduction

Error reduction is an incredibly important step in the manufacturing process, even minor errors can snowball into major defects down the line.

Using 2D drawings, changes can be documented more easily and any potential error can be quickly identified.

Ease of Use

A low barrier to entry is critical for manufacturing, many old-school machine operators are still not comfortable with using computers. 2D drawings are an old and basic designing tool that almost all production teams know how to use. No need to mess around with complicated computer models and software.

You can simply print the 2D drawing on paper and hand it to the CNC machine operator.

This decreases the error probability in the production process and decreases the time and cost of the overall product production.

2D Drawings vs 3D Modeling

Multiple factors differentiate 2D drawings from 3D models. The following are key factors that differentiate the two design techniques.

Dimensions

In a 2D drawing, each projected section/view is properly labeled with its dimensions. While 3D models often require you to select a specific surface to check its dimensions. 2D drawings, specially printed ones will have the proper dimensions in front of you at all times.

Portability

2D drawings can be easily printed on paper, rolled up, and carried around a work site. While 3D models require a table or laptop to be on hand all the time. A bonus to the 2D method is that you don’t need to charge your paper drawings.

Visibility

A minor issue of 3D models is their visibility in direct sunlight. If you are working on a project outdoor, you will be constantly under direct sunlight. Laptop and tablet screens have come a long way but they are still not good enough for outdoor use.

Size Restrictions / Readability

2D drawings are only limited by the size of the paper. Most industrial drawings are printed on A1-sized paper (23-3/8 x 33-1/8 in). 3D models are limited by the screen size of your laptop or other electronic devices, which are typical 13-17 inches in size.

Using 2D Drawings for Machining

Here are a few examples of the applications of 2D drawings in machining workloads.

2D Drawings for CNC Machining

In most CNC machining projects you work on one side of the workpiece at a time. This requires accurate dimensions and views for the required product. 2D drawing provides this information with standardized systems of identification (dimensions, types).

2D Drawings for Sheet Metal Fabrication

Sheet Metal Fabrication is a process that bends and cuts flat 2D sheets of metal to create a 3D final product. 2D drawings are the only viable method for designing sheet metal parts. 3D models here are only used for references of the final shape.

2D Drawings for other Machining Processes

Like sheet metal forming, many other manufacturing techniques rely on cutting flat sheets of material. Techniques like laser cutting, metal stamping, and CNC routing all benefit from 2D drawings.

Conclusion

Model-based drawings are limited by software availability and electronic displays. 3D models are quite beneficial for certain applications and environments. But 2D drawings are universally compatible with all manufacturing processes. 2D drawings are easier to share with others and are simple enough that even layman can understand them.

Why QBH Technology is the Right Choice for your Manufacturing needs?

QBH is one of the top OEM and ODM service providers in China. We offer several machining services including Sheet Metal Fabrication, CNC Milling, CNC Turing, and more.

Our customer confidentiality policy ensures your designs will be protected. We also offer drawing services to customers, where our professional engineers will guide you in designing your product.

So, don’t let this golden opportunity slip by, and Contact us Now!