You know that millions of people are doing different businesses throughout the world. Their business depends on their interest and financial needs.For this purpose, using the laser sheet metal cutting machine is becoming trendier. Laser cutters are not just crafting tools, but you can also prototype product designs. Using a laser cutter, you must follow the following instructions to bring your product idea to life.

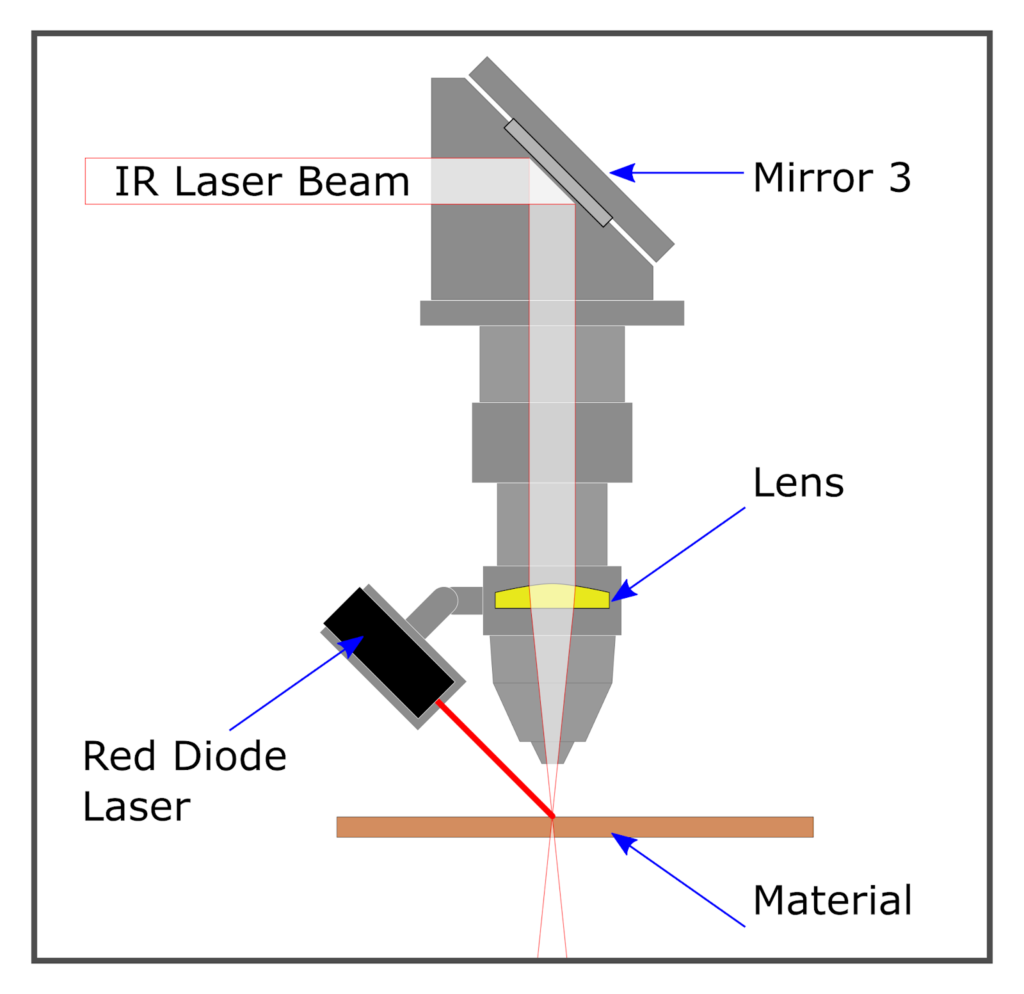

1- Choose an Appropriate Laser Cutter

Choosing the right laser cutter to bring your product idea to life is compulsory. It would be helpful to choose an appropriate laser cutter. Choosing the right laser cutter may look very simple and easy, but it is a very complex process in reality. Purchasing the wrong laser may not provide you with your desired high-quality products. A variety of laser cutters are available in the market, and you must have accurate information and knowledge about the laser cutter you will purchase. You must know accurate information about the size of the laser cutting machines as it comes in various sizes. Looking at the reviews and consulting with buyers about different laser cutters may also prove helpful in purchasing the right laser cutter. It would be good to go for the laser cutter with the best customer reviews.

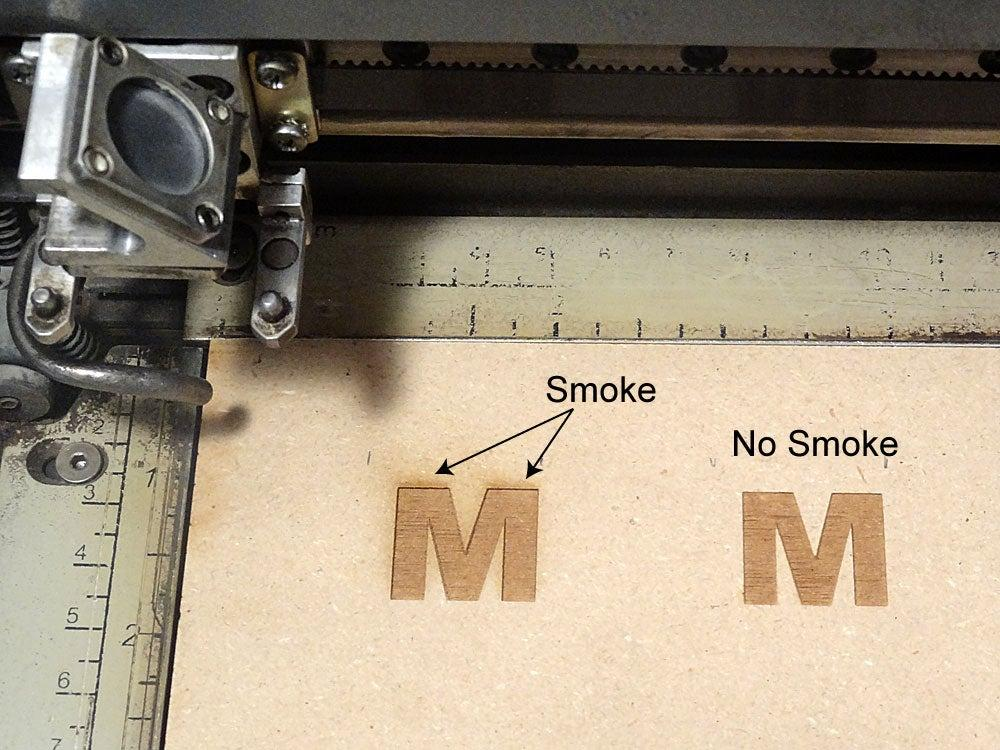

2- By Practicing with Your Laser Cutter

Before creating a product, you must have accurate information on using a laser cutter. If you have no idea of the appropriate use of a laser cutter, then you can never bring your product idea to life. For this purpose, you must do the practice using a laser cutter. The training programs may also help you in using the laser cutter properly. Using scrap material before starting the crafting of the physical prototype can be helpful and reduce the waste of assets.

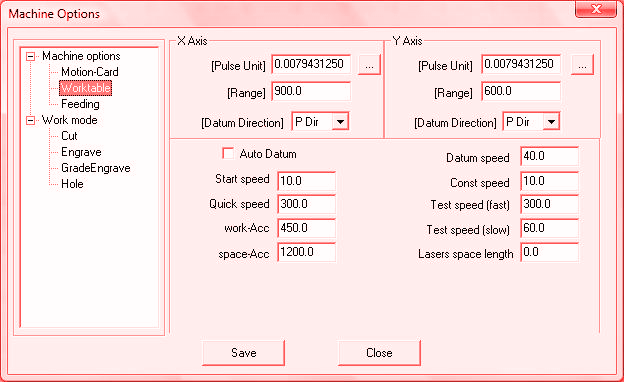

3- Gain Correct Information about the Laser Cutting Machine Settings

Gaining the right information about the laser cutter setting is compulsory to bring your product idea to life. If you are not familiar with the proper laser cutting setting, you can’t get your desired product. Most software is provided with the laser cutting machine. By using this software, you can change the setting of the machine. Doing the right setting helps inappropriately cut and alter the materials according to your choice without any damage.

But, if you neglect the software setting, you cannot get your desired product resulting in damaging the material. You can also change the machine power using the laser cutter machine software. So you have to set proper power by clicking the software button to give the exact cuts of the material. Moreover, it would be good if you also had a good idea of the speed setting of the software program of the sheet metal laser cutting machine.

4- Take Precautionary Measures

Safety should be a priority no matter what machine you are using. The same is the case with laser cutting machines. The improper use of the laser cutting machine or any other machine such as cnc machining can lead to severe damage. If you neglect proper precautions while using laser cutters, you may face eye burn or other serious eye problems. So, to prevent severe damage, you must use eye protection.

Moreover, it would help keep a distance from the laser machine while using machining can be helpful to prevent damage. You must properly clean the machine to prevent any damage from a fire at the end of the laser machining process.

After completing the machining process, the proper shutting down of the machine is also compulsory for protection from any damage. So, by following these precautionary measures, you can prevent danger, thus bringing your product idea to life.

5- By Creating a Digital Prototype

While manufacturing a product, you must keep manufacturing the product at a much lower cost. A manufactured product with a high cost only provides you with a loss instead of profit. So while manufacturing products using a laser cutter, you must avoid manufacturing direct physical prototypes. Before manufacturing physical prototypes, you must design digital prototypes.

The main reason for this is that it may result in a material loss when you directly design a physical prototype. Due to the loss of material, you may face the high cost of the manufacturing process. Thus to avoid high costs, you must design the digital prototypes first.

You can highlight any mistakes and flaws by designing digital prototypes and can improve these mistakes. Different soft wares can help you in creating digital prototypes. Thus creating digital prototypes can help you in saving both money and time.

6- By Creating a Physical Prototype

After creating a digital prototype and learning the mistakes and skills of using a laser cutter, you have to create a final physical prototype. Creating a physical prototype with proper laser cutting skills saves time and reduces costs. Such physical prototypes bring your product idea to life.

7- Refining and Redesigning

You can also learn a lot of mistakes while creating physical prototypes by using laser cutters. Making mistakes is a common problem, and you can overcome this problem by refining and redesigning the products. After refining and redesigning using laser cutters, you can bring your product idea to life.

Conclusion

Using laser cutting machines is no doubt a difficult task. A little negligence in using the laser cutter can lead to severe damage and ultimately damage your desired product. It would help if you use the laser cutter with proper precautionary measures and have detailed information about the setting of the laser cutting machine.

The improper information about the setting of the laser cutter can permanently damage your product. Moreover, you must also avoid creating direct physical prototypes because you may create undesired cuts. So, initially, you must create digital prototypes.

Physical prototypes can show you your flaws and mistakes and have an important place in the manufacturing process, so it’s natural to make mistakes to create something new. Practice makes you perfect, so you can use laser cutting or metal fabrication to bring your product idea to life by keeping in mind all the instructions mentioned above.