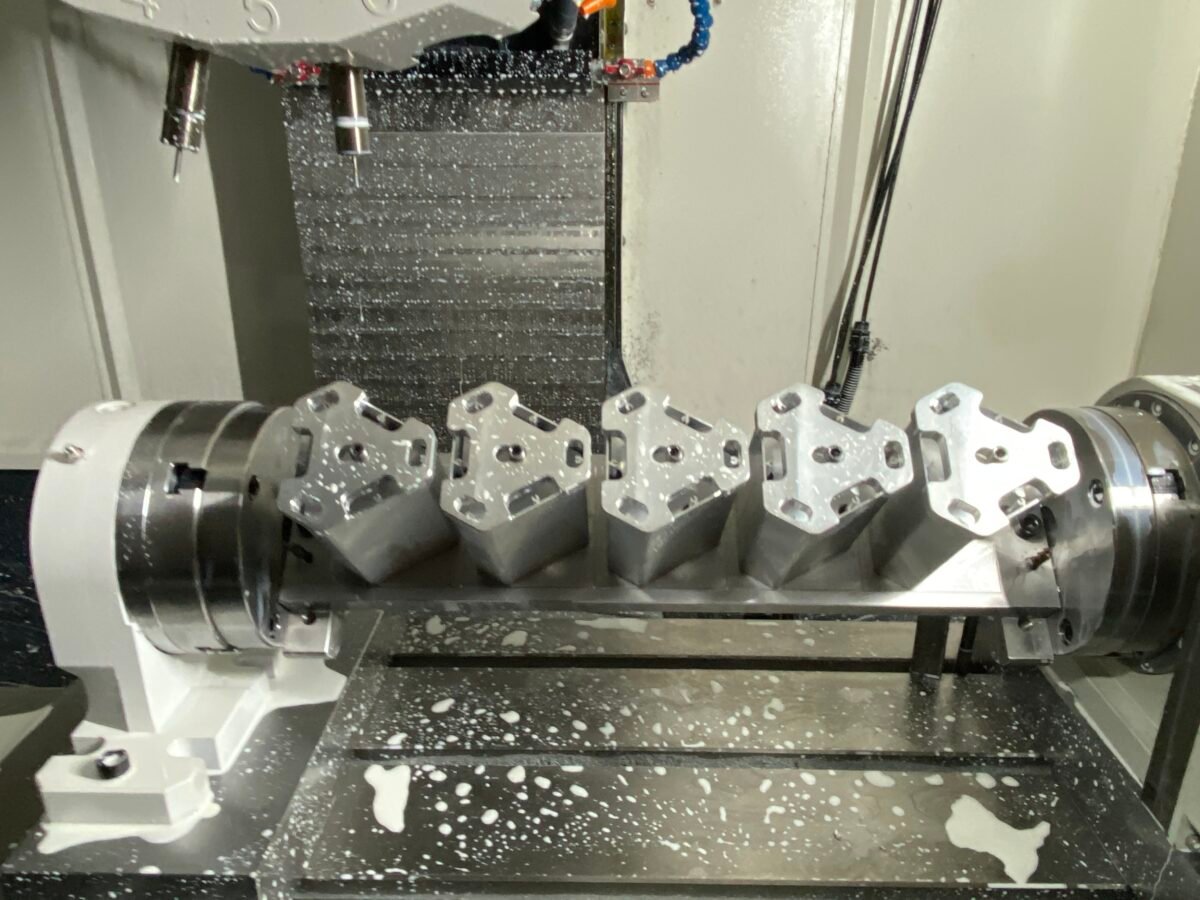

CNC machining of aluminum alloy is becoming more common. It is because of the broad use of aluminum alloy parts.

When the manufacturing process is complete, the maker needs to deal with the item’s finish. It is possible to handle the surface of industrial components and parts in various ways.

Component makers select various surface treatment methods. These methods are anodizing based on their technical capabilities and practical needs.

We use Anodizing in the aluminum sector. The best manufacturer for such types is QBH Technology.

It is because of its long durability, high corrosion resistance, and improved aesthetics. You must be knowledgeable with:

· Anodizing

· The most prevalent anodized aluminum hues

· The process of anodizing aluminum objects to color them.

Anodized Aluminum!

We treat Aluminum to get a long-lasting finish as anodized aluminum. Electrochemical processes manufacture anodized aluminum by immersing aluminum in tanks.

The tanks are where the anodic coating is grown from the metal itself. If you want your designs in a matter of hours. You need to use the services of QBH Technology’s high-quality production options.

In contrast to other anodized aluminum materials, this anodized aluminum never flakes.

It is more durable than any other similar material on the market. Anodized aluminum is 3X stronger and 60% lighter than the raw material compared to others.

What Makes Coil Anodized Aluminum So Different?

A regulated coil anodizing process ensures that anodized aluminum is of:

The highest quality has the Lowest Possible Processing Costs: It drags unwound coils of raw aluminum through a succession of tanks.

The tank is where we clean them, anodize, color, seal, and rewound. We’re left with anodized coil aluminum of high quality.

Color-matched to our client’s specifications: We roll the anodized metal, ready to get to its final destination. Coil anodized aluminum reduces the number of processes. The processes may vary.

Typical batch anodizing process Reducing costs: The degree of consistency in the finished product’s appearance.

We need to establish an electrical contact point in the batch anodized process. We need it for the electrical current to aid in the development of the anodic layer. We can connect each component anodized with a metal hook or rack.

These racks often leave burn markings on the material, also known as rack marks. We need to cut off these marks, adding more waste and cost to the production process.

We expose every inch of the coil to the same length of time throughout each stage of the production process. It ensures a consistent color.

We then dip the aluminum into the tank during processing instead of coil anodizing. This process results in the metal spending more time in each part of the process. It also causes uneven color and thickness of the anodized coating.

We need to attach each metal that goes into the tanks to the racks and attaching them helps in handling damage that increases costs.

There are many benefits of using this method. You may get reduced handling and cost-saving. You will reap these benefits if you use a continuous coil anodizing process.

What Are the Advantages of Anodizing Aluminum?

▬ Durability

While aluminum is already a strong metal, anodizing it increases its tensile strength. As we know, it is 3X more durable than normal aluminum. Anodized aluminum is color-resistant and won’t peel even when treated to add color.

It is one of the most durable and adaptable metals on the market.

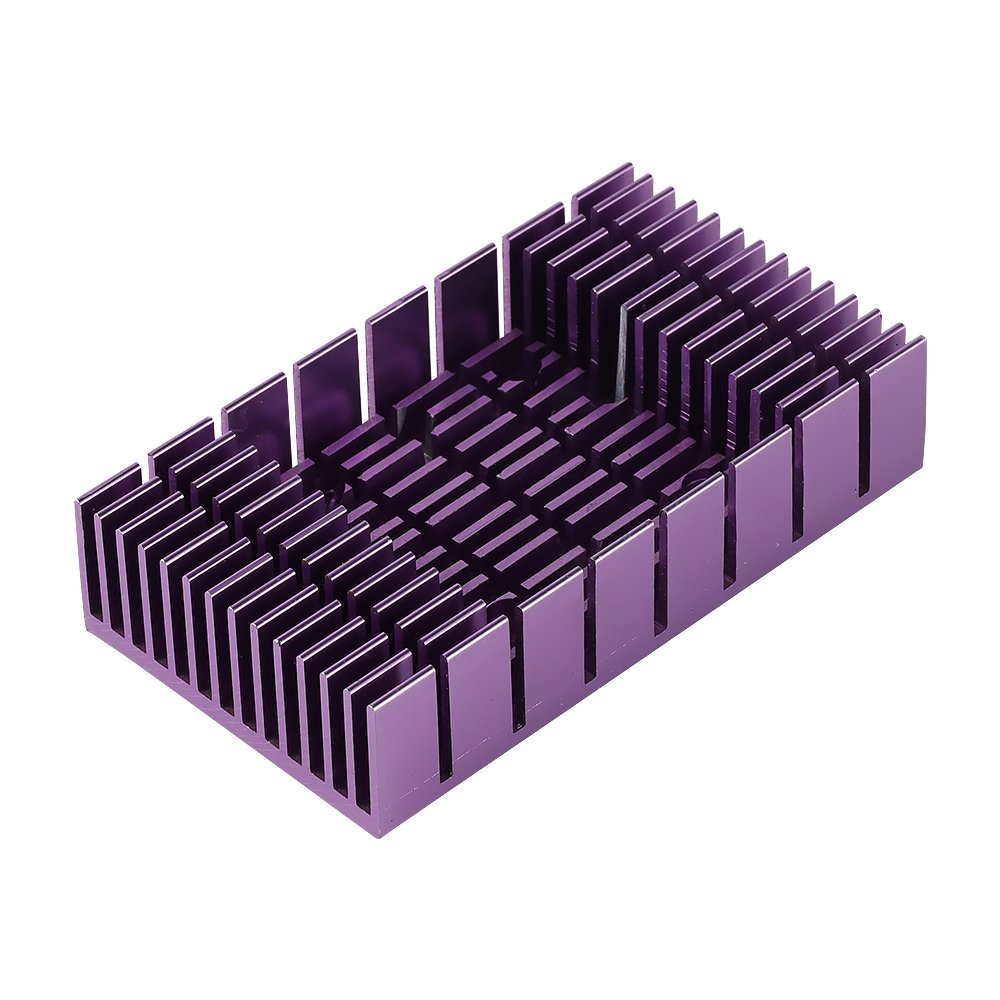

▬ Appearance

Decorative anodized metal lends a touch of elegance to any object. It’s possible to anodize metal. We can use a method that leaves a matte or brilliant appearance if left natural.

▬ Options for Custom Colors

It is possible to match almost any brand colors. It is because of the open structure of the anodic layers before sealing.

The material’s adaptability means that we can create it to mimic the appearance of others. It may be complete without the danger of deteriorating.

Lorin has several worn appearance finish choices if you prefer that aesthetic.

The color can’t fade, peel, chip, or flake off an anodized aluminum surface due to the nature of the material. We may count on Lorin’s UV-stable colors to stay as long as you use them.

▬ Lightweight

Anodized aluminum is lighter than stainless steel, copper, or brass. It weighs around 60% less. It reduces the cost of transporting the material. We may use it to address a wide range of design challenges.

▬ Cost

To ship aluminum anodized to a project site or industrial plant. Due to its high strength-to-weight ratio, it has a cheaper cost per square foot. It is cheaper than steel, zinc, bronze, brass, and copper.

Yet, the visual impact is the same. Aluminum has a lower environmental impact than most other materials. It is because it is abundant and renewable and the only metal that is 100 percent recyclable.

The friendly anodizing process further reduces aluminum’s environmental impact. These aspects combine to create a more versatile and long-lasting product.

Basic Anodizing Knowledge!

The anodizing process is like other surface treatment processes. We may use it to treat the surface of metal objects. Various parts machining businesses acknowledge the anodizing technique. It is because it enhances the aesthetics and corrosion resistance of the components.

This electrochemical cell reaction occurs when we expose aluminum to an acidic electrolyte. The electrolyte should serve as the cell’s anode and cathode.

Anodizing is a popular electrochemical procedure in the aluminum processing industry. It is because it enhances the surface qualities of aluminum processed goods.

Various Methods of Anodizing!

We can do anodizing can in various ways. There are three main categories:

· Hard anodizing

· Soft anodizing

· Combination of both.

There are three types of anodizing procedures, and each process has distinct characteristics. The characteristics are various coating strengths, different electrodes, electrolytes, and energy requirements.

Type 1: Anodizing Process

We know it as “light anodizing” and types 1 anodizing. Light anodizing gets its name because we use butyric acid as the electrolyte in Type 1 anodizing. We use aluminum as the anode.

The + ions on the anode expel, creating microscopic grooves on the metal surface. These groves will come as the current flows through the electrolyte. Compared to normal aluminum, Type 1 aluminum is more resistant to heat and corrosion.

Type 2: Anodizing Process

The electrolyte feedstock changes from butyric acid to sulfuric acid in this process. Type 2 anodizing produces a thicker oxide layer. It is because sulfuric acid is stronger at ejecting + ions. It creates deeper grooves in the metal surface.

Type 3: Anodizing Process

The type III anodizing technique is often used to produce aluminum metal goods. Type III anodizing differs from the previous two. Type 3 utilizes both voltage and a strong acid on the electrolyte. Type II anodizing uses sulfuric acid as a strong acid.

Steps to Color Anodized Aluminum!

It isn’t easy to impart color to metal objects through anodizing. There are many variables in the anodizing process.

It places more demands on the skill set of the anodized than typical painting or powder coating does.

Step 1: Aluminum Parts Cleaning and Etching

Anodizing aluminum items is a complex process that involves a lot of time and effort. The anodizing process begins with the operator cleaning aluminum components. The components are soap, cleaning and ventilating them, and drying them before etching.

We cannot stress enough how crucial this step is. Etching is also crucial in coloring aluminum goods. It is because it removes trace metals from the surface.

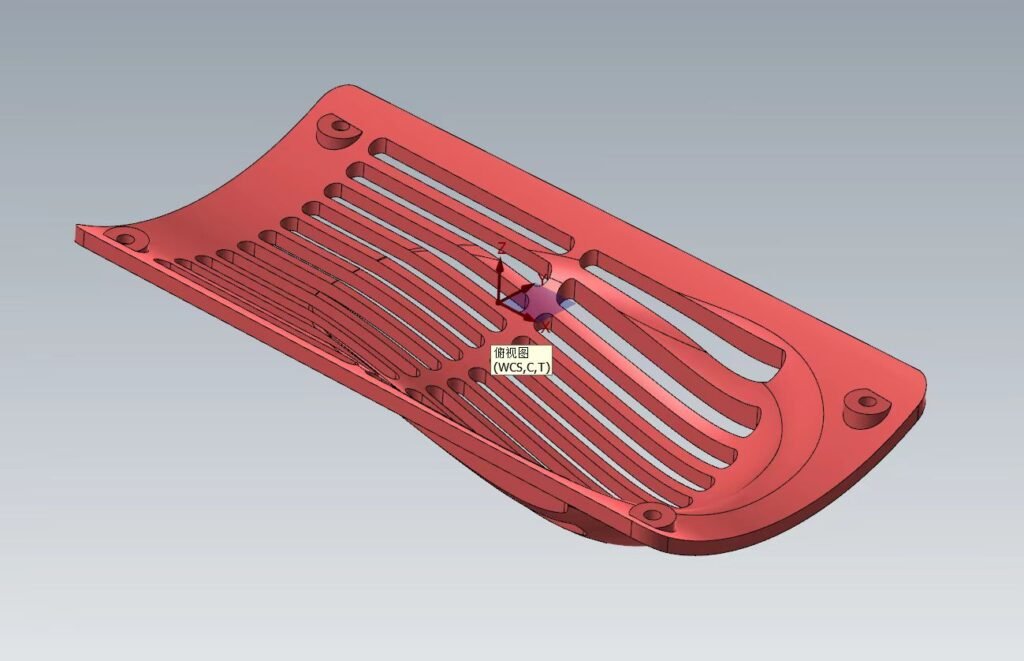

Step 2: Create a Layer of Oxide

We can anodize the aluminum pieces once we etch and clean them. We may color aluminum goods using three methods to meet specific client requirements.

Step 3: Including a Vibrant Shade

Electrolytic Coloration: The most frequent coloring method for aluminum components is electrolytic Coloring Using a solution containing metal salts, soak aluminum items.

The salt solution creates a resistant coating to UV radiation. It can do so when used to plug microspores on metal surfaces. It is important to remember that the process of coloring has constraints on bronze and black.

Pigment Coloring: The aluminum component of it must be further processed. We must put it in a dye-containing container. All the microspores on metal get filled with dye.

After that, we boil them in the following deionized water. The boiling continues until the aluminum product is completely colored.

General Coloring: The palette used here is rather straightforward. Anodizing and coloring the metal together with dyeing it black or bronze is the goal of this process. Aluminum items might be more resistant to wear. It is because of the coloring process’s benefits.

Sand Blast: Repairing flaws and polishing the surface are important steps in finishing.

Step 4: Sealing

When needed to hold dye molecules in place in the anodizing process. The sealing prevents undesired molecules from entering the gaps. We need to keep sealing temperature at 180-200 degrees F in hot water, or roughly 93 degrees Celsius.

We see improvements in the oxide film’s anti-pollution, corrosion resistance, and resistance qualities. It is because the pores in the porous oxide film generated after iodization.

Colorless and translucent, the oxide film is what you’d expect from an oxide layer.

Final Thoughts

Electrolytic anodizing is a crucial procedure in surface finishing, utilized to enhance the finished product’s optical relativity, aesthetics, etc. The anodizing process and its advantages are covered in this article.

It also discussed the numerous variables that go into the art of color matching. The anodizing procedure is no doubt complicated. QBH Technology, on the other hand, is your best bet for high-quality products at reasonable prices.