The process of coating a thin layer of zinc on the surface of iron or steel to protect these from rust.

This layer protects the metal in the following ways:

(1)This layer works as a barrier and doesn’t allow the moisture or air to come in direct contact.

(2)If the layer is broken down it also protects by creating an anode.

Methods of galvanizing:

Galvanizing can be done by any of the following methods.

Why is galvanizing done:

Galvanizing is done to protect the surface steel or iron from pre-mature rusting.

What is rust:

Rust is an oxide of iron that is formed on the surface of the steel due to moist air. Actually, rust is red flasks of iron oxide which are porous. These iron flasks do not stop the further rusting because moisture can pass through them and a whole piece of steel may be destroyed if not protected.

Pre-galvanizing:

This is the primary method of galvanizing. The metal sheet is rolling with a cleaning agent like mineral acid (hydrochloric acid) and then dip in the hot molten zinc bath and immediately recoil. This method is beneficial as the coiling steel sheets can be galvanized rapidly.

Electro-galvanizing:

In this method, the sheet of steel is an anode, and zinc solution act as an electrolyte. when the electric current pass through the solution zinc ions reduces to form zinc metal. Finally zinc metal deposits on the surface of the steel. This is an initial step performance during the time of production.

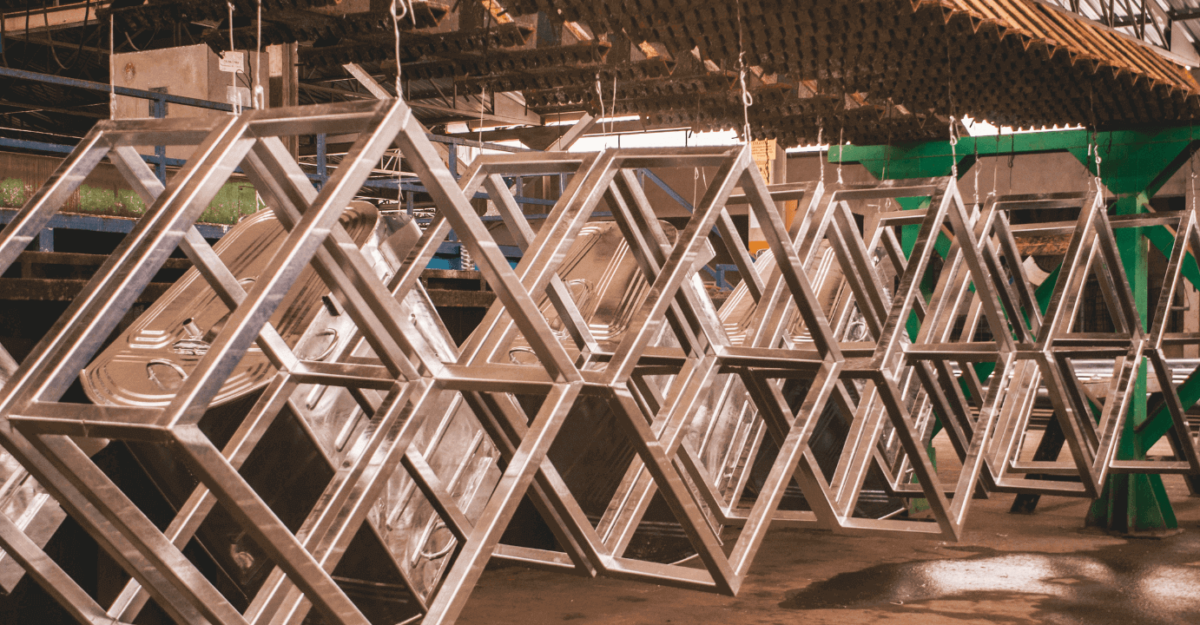

Hot-dip galvanization:

This is the simplest process of galvanizing. The process intimates the dipping of metal sheets in the melted hot zinc metal bath. It has three following steps.

In step one, the metal is cleaning a base metal chemically or mechanically. Until all the flasks are finishing from the metal.

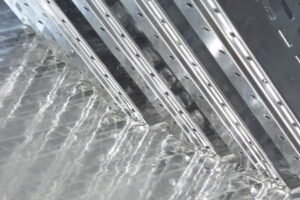

In the second step, the base metal is dipping in the hot melted zinc. The temperature kept for this purpose is more than 800 oF. Zinc metal and base form a metallurgical bond between them.

In the third step, the metal is pull-out from the zinc metal bath. The zinc layer reacts with oxygen from the air to form zinc oxide. Zinc oxide further reacts with carbon dioxide to form a final protective layer of zinc carbonate.

Galvannealing:

This is actually an alloying method. In it, metals are alloyed to get the required materials. This is the method of combining annealing and hot-galvanized metal. In this process, a particular layer of zinc is the deposit on the surface of the steel. The galvannealing process use by hot-dipping and instantaneous annealing produces a matte grey finish.

Galvannealed steel is a zinc-iron alloy product. In this, the metal is first coated by the hot-dipped process and then heated to get alloying between zinc and steel. The resulting finish is a sluggish matte surface.

Benefits of galvanized sheet:

Galvanized sheets of metals like iron or steel are widely in industries and in daily life.

Following are some uses of galvanized sheets:

- Sunshades

- Covers of buildings

- Furniture covers

- Framewear

- Balusters

- Packing sheets

- Toys covers

- Electronics covers

Availability and versatility:

Hot-dip steel is versatile and readily available. Galvanizers are present in the north-America. They produce a variety of shapes and qualities, sizes can hot-dip galvanized 24/7/365-rain or shine.

Furthermore, zinc solidifies immediately when it is removed from the bath so there is no delay when schedules are tight. On the other hand galvanized sheets are saves very easily, even in the open environment because ordinary environmental factors have no effects on the galvanized sheets.

Hot-dip galvanized steel prepare from two naturally occurring primary components i.e iron (steel) and zinc. Iron is the 4th abundant metal that exists in the earth’s crust while zinc is the 24th abundant metal.

Low cost:

This process is not so expensive. We can prepare iron or steel sheets at a low cost. These are readily useable when delivered. There is no need to give them extra time or money like coloring, polishing, etc.

Longevity:

A piece of the sheet that is galvanized contains a very long life. These sheets may have 50 years of life in ruler and normal urban areas. If used in a moist environment its life span is about 20 years. If galvanized metal is present in building materials it will give comfort for many years. It also increases the appearance and durability of the steel.

Galvanizing gives great value for money:

Galvanized sheets of steel prepare at a low cost. These are prepared with high quality, minimum time, and are readily available for use. This is done by a very simple process as the hot-dipping method.

If we use some other methods or alternative methods are costly and they take a long time to utilize them. Like a painting is a much more time-consuming and laboring process.

Galvanizing is the authentic, systemized process:

Galvanizing is a fast, simple, and environment-friendly process. There is no production of any pollutants or contaminants during this process. There is a clear standard in the thickness of the coating on the metal sheet. A very thin layer of zinc makes a reliable connection with steel and makes its durability long-lasting.

Also, zinc makes a very strong bong than any other chemical or mechanical bond. Zinc metal becomes a part of base metal, making it extraordinarily resistant to damage.

Hardness:

The metals after galvanization become very rigid and hard. So we use these sheets in the manufacturing processes. Where we need very hard structures. Such as:

- Stairs

- Terrace

- doors

- Windowpane

- Marquee

- Building frames

- Canopies

- Ductwork

- Handrails

- Fences

- Industrial walkways

- Step ladder

- Staircases

- Street furniture

- Support beams

- Sunporch

Sacrificial anode:

If the coating of zinc on steel or iron is breaking up this acts as an anode. The anode protects the inner metal from rusting. If the rusting starts then the zinc metal will crude first so this is acts as sacrificing anode.

Rust protection:

The elements of iron present in the steel are improbable to rusting. But when the zinc is mix in the steel the zinc protects the iron from rusting by keeping the moisture away. Galvanized steel is very protective and has sharp corners. Any other metal can’t protect the iron like this.

Electronics:

The casing of most of the electronic appliances forms from the galvanized sheets. Computer casings are generally forms from galvanized sheets. As galvanized sheets protect from moisture.

Environmental friendly:

Galvanizing processes and sheets are environmentally friendly as there is no production of any pollution. Zinc exists in nature. It is also a compulsory component for the normal growth of animals, plants, and microorganisms. Zinc is a trace nutrient for the normal growth and reproduction of humans. Its production didn’t cause pollution. Both the components i.e iron and steel are 100 % recoverable or recyclable.

For using the galvanized steel there is no need for extra maintenance. maintenance-free Longevity means there is no need for extra resources for its maintenance and protection. Eliminating maintenance only produces zinc products. These products are already present in the environment. These zinc products don’t have harmful effects on the life present in that environment.

Sustainability:

Sustainability is the capacity to endure in a relatively ongoing way across various domains of life. It is a social, environmental, economic commitment to growth and development that meets the needs of the environment without compromising. As the social pressure continues to develop a demanded quantity of material. Hot-dip galvanizing provides maintenance-free, environmentally friendly, galvanized steel, beneficial for future generations.

Piping :

Galvanized piping change the concept of piping from cast iron to galvanized piping in the 20th century. The cast iron piping causes the mixing of rust and other chemicals in the water supplies, proximity to the electrical grids, whether the piping is covering inside or outside with zinc metal.

To increase its longevity galvanized pipes are joining with epoxy resins. Which is a chemical compound that comes from petroleum. Epoxy provides strong adhesion, flexibility, and strength.

Playground equipment:

Playground equipment is made up of galvanized pipes or sheets because these are rust-free. Like bicycle racks, jungle gyms, etc.

Transportation:

Cars, aircraft, bicycles are more consuming machinery of galvanized equipment. The uses of galvanized sheets in other industries are as follows:

- Hoods

- Fenders

- Parking brakes

- Seating

- Spring housing

- Roofing

- Oil pans

Wire-rope:

Wire-rope is a highly stressed component and hot-dipped sheets may reduce the strength of the steel due to hydrogen embrittlement. So the steel becomes brittle.

To solve this problem we use stainless steel in the manufacture of electric cables, bindings, etc.

In short galvanizing protects from corrosion, rust, moisture, and scratches.

Galvanized sheets are everywhere:

Galvanized sheets are very popular in almost all industries. You will find galvanized sheets everywhere on your work or in your households. Galvanizing is a low-cost trustworthy method to increase the life of your metal. select the method which suits your work and talk with your contractor to ensure the life of your metal. Some industries which are widely using these sheets are as follows:

- Telecommunication

- Construction

- Solar industries

If you have any confusion or question. You are free to please ask in the comment box. And leave a comment. We will get back to you as soon as possible. Thank you.

FAQs

How the Galvanizing protects the underlying iron or steel?

- The zinc coating, when intact, prevents corrosive substances from reaching the underlying steel or iron.

- Additional electroplating such as a chromate conversion coating may be applied to provide further surface passivation to the substrate material.

- The zinc acts as a sacrificial metal to protect the underlying iron/steel and thus acts as a sacrificial anode. In the event the underlying metal becomes exposed, protection can continue as long as there is zinc close enough to be electrically coupled. After all of the zinc in the immediate area is consumed, localized corrosion of the base metal can occur.