Designing custom sheet metal brackets style is a demanding process. Although it is a backbreaking process. But provides the most important designing and appliances of metal sheet bracket styles. Additionally, This process provides you a variety of styles and shapes to design. Usually, Sheet metal is the most adaptable material for designing brackets style in the manufacturing industry. The sheet metal may be of aluminum, nickel, titanium, tin, steel, brass, or other metals.

For designing sheet metal bracket styles, there are many advantages to use sheet metal in the process. Because the sheet of metal offers significantly lower material cost.As well as, it gives beneficial usage to not only the non-metal alternatives, even other types of materials of metal fabrication as well.

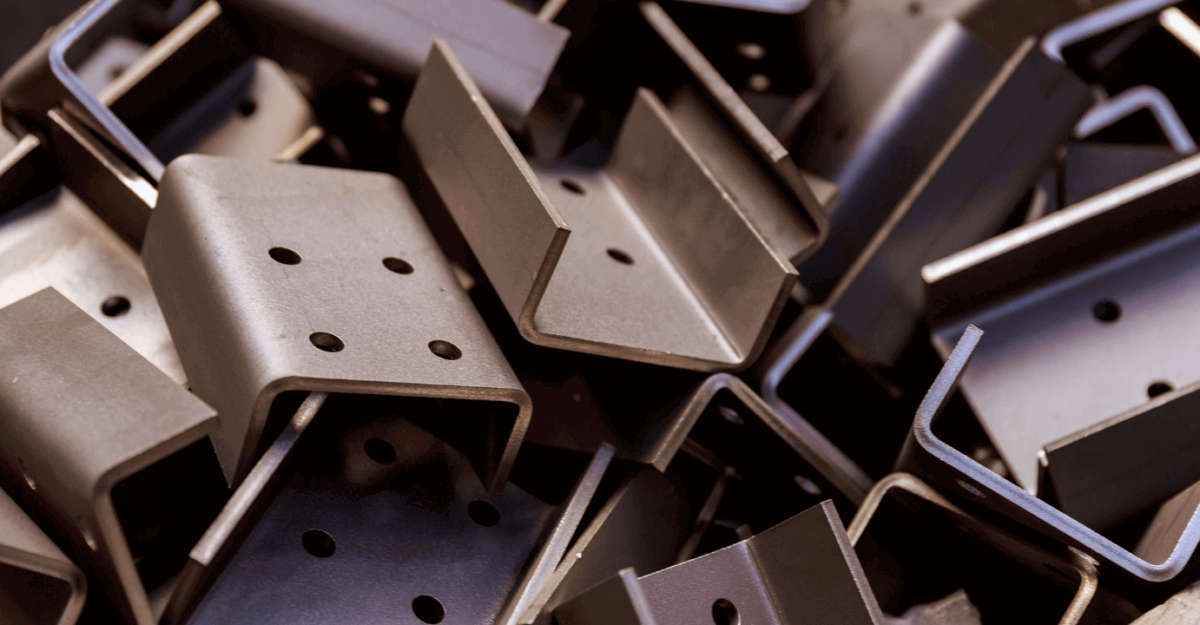

Additionally, sheet metal brackets are present in a variety of styles. But, a specific style of sheet metal brackets is designing to perform specific requirements in the manufacturing industry. As well, metal sheets play a significant role in designing brackets style.

The major role of these bracket styles is mounting a component, compatible with a specific surface shape. According to the situation or requirement, specific bracket styles of sheet metal are designing in the manufacturing industry. Commonly, bracket-style is may introduce as it is an intermediate component. Which plays a role to fix one thing. For example, it may fix your shelf or wall, furniture sections commonly.

According to your tooling requirements, there may design different custom enclosures in the manufacturing industry. Whether as, a variety of bracket styles and custom standalone components may design according to customer order of requirements.

For the sheet metal bracket styles designing, In this process, there are many actions to do with a metal sheet. such as cutting, stamping, punching, shearing, forming, bending, welding, rolling, riveting, drilling, tapping, and machining. When metal sheets are performing all these steps in the fabrication process, it moves forward to the next door. Then, steps to do with components such as brushing, plating anodizing, powder coating, spray painting, silk screening, and marking.

Introduce yourself to metal sheet brackets, and their usage.

Metal sheet brackets are devices that built a collection between two objects. Brackets play an intermediate role in fixing things. Such as furniture sections, or flooring. Commonly, stainless steel, brass, carbon steel, and aluminum are significant metals. Which plays a significant role in metal sheet brackets in the manufacturing industry.

Although, metal sheet brackets are present in a variety of shapes in the industry. The most important and specific brackets are functional. Brackets have holes. Because these holes are helpful to feed them by screws or other fasteners. Best brackets provide functionality as they are responsible to build a connection and support between objects.

The major function of brackets is to provide support and connection between two objects. These objects may be flooring, shelving, countertops, or sections of the furniture. Brackets are also used for decorative purposes.

The common manufacturing process for brackets is casting and CNC machining. We can use the most important and best way to get simple brackets by a process. Which is sheet metal fabrication. Through, these manufacturing processes, we can get functional brackets.

The thickness of the metal sheet may vary.

In the Metal sheet bracket styles designing, the thickness of the sheet plate may be 0.9mm_ 20mm. The thickness of the metal sheet is according to the requirement of the final product in the manufacturing industry.

Types of metal sheet bracket styles

The best way of designing metal sheet bracket styles is metal sheet fabrication. This process manufactures several types of bracket styles. Types of bracket styles are beneficial and useful according to their application. Manufacturing industries manufacture or design bracket styles according to specific requirements and bracket-style applications. Some common types of bracket styles are

- L-bracket

- U-bracket

- Z-bracket

- Gusset bracket

- Offset bracket

Basically, the process of metal sheet fabrication or sheet metal bracket styles designing starts with a flat material. It is the non-additive and non-subtractive process of manufacturing. The protocase designing is the best way to quick and easy designing. In this process, in-house CAD software installation provides an easy way to designing of bracket styles.

All bracket-style are designing at a specific Angle. Many bracket-style need angles of 90 to 120. The angle of the bracket-style is according to its requirement of manufacturing. The metal sheet bracket designing process is according to the basic principle. As, installation of software CAD, The 3D CAD files converting into codes. They are easy to understand by machine and working according to that code of language.

L-bracket

It is a common type of bracket style. It looks like the L alphabet. As its name indicates. In L-bracket often bending along a single axis, there creating 90°angle. L bracket application is to capture objects according to their shape of manufacturing.

U-bracket

It is also a common type of bracket-style designing, by U-shape.

There is bending along 2 axes. U- brackets play a significant role to grip an object or mount parallel objects.

Z-bracket

It is a specific shape bracket that looks like the Z alphabet. This bracket bend one flange inward and another outward making a profile of Z shape. It is specific to its applications.

Gusset bracket

It is a type of bracket that has load-bearing capacity. You can do welding to the gusset bracket, or maybe applicable as a single piece.

You may design a gusset bracket in any size according to the requirement of your application. It may do some extra welding to the gusset bracket for your specific application. That will provide you with some extra support for the components.

Offset bracket

It is a similar style to the Z-bracket. It plays an important role in mount parallel objects. You may contain components by offset bracket.

Bracket styles designing purpose is to support two objects in the same plane. A flat bracket is the name of the transformer strap. It is a type of bracket that can help both square and radius ends. As well as, round or slot holes in it.

Angle bracket is also a type of bracket-style. Application is to hold two perpendicular objects together in a specific assembly and strengthen the angle.

Along with, these types of bracket styles. There are many other types of bracket styles. That is specific in their range, tolerance, application, and requirement. All bracket styles are specific in their applications. Such as,

- Flat bracket

- Angle bracket

- Mounting bracket

- Terminal board bracket

- Offset bracket

Features of sheet metal bracket styles

Metal sheet bracket styles may vary in thickness range. such as it may be from 0.9mm-20mm. It provides the ability of manufacturing from a sheet ( <3 mm) or for metal sheet brackets plate (>3mm).+/- 1 degree of tolerance is commonly acceptable in manufacturing industries. It depends on the manufacturing of specific products. Bracket styles provide you a huge variety of shapes. Which are perfect for their design and application of usage.

There are holes in bracket styles. These holes may be round shapes or square shapes according to requirements and applications in the industry.

This provides an easy way for fasteners for working and drilling through the point of mounting. If you want to design bracket styles. You should use the protocase designing process. In this way, CAD software installation provides you an easy way to designing custom bracket styles.

In the manufacturing industry metal sheet, brackets styles have specific features and functions according to their manufacturing purpose. Such as,

Angel bracket style1,2 contain round holes and square ends .or round holes with radius and square ends. It’s all according to their styling in the manufacturing.

The mounting bracket contains slot and round holes radius and square ends.

Important instructions to designing custom sheet metal bracket styles

If you want to control your costs while you are designing bracket styles. There are some basic tips for designing bracket styles. You should follow these important instructions to do so.

While you are designing sheet metal bracket styles. Keep in mind if your hole pattern is symmetrical, Then you should keep spacing according to it. If you want to design some specific holes pattern. Then you may require a specific hole pattern, that is a matching pattern.

These specific patterns of holes may increase the costs of metal sheets in the process of fabrication. You should keep your designing simple and symmetrical. Use protocase designing to design bracket styles. From all types of bracket styles, L-bracket is easy to design and low in cost.

You can do designing of metal sheet brackets with the best CAD software installation. But there are important things to keep in mind while you are creating a design by metal sheet fabrication.

Commonly, bracket-style of L shape would be designed with an angle of 90° in an easy way. You can create the design at different angles which are more than 120 degrees. However, keep in mind less ductile metal articles and order to the bend.

If you have any questions or confusion. You are free to plz ask in the comment box. And leave a reply. We will get back to you as soon as possible. Thank you