Engineers need to understand a part’s use cases, manufacturing process, and material to know the suitable method for their creation. Here we will discuss some ways to make custom metal parts.

The metal parts manufacturing process, such as shaping, assembling, cutting, and bending, is called metal fabrication.

You know that dozen of metals are commonly available throughout the world. These metals are widely used in household items, cnc machining, sheet metal fabrication, and various industries. All the metals are not the same but vary according to their properties. Some metals are soft, and others are hard metals.

Soft Metals

The soft metals, as the name shows, are soft. These lack too much hardness. The soft material in the soft metals can be a surface engineering material. The soft material may be a lubricant for sliding and rolling applications. Soft metals can improve the ability of anti-wear and also aids in improving the friction of the mechanical components. Moreover, soft metals also prove helpful in increasing the equipment service life. Soft metals include zinc, silver, gold, tin, etc.

Elemental aluminum is highly malleable and soft, so it is not good for mechanical purposes. But you can use aluminum by blending it with other elements such as zinc, copper, silicon, and magnesium, making it lightweight and strong. It uses in automobiles, airframes, and consumer products.

Hard Metals

On the other hand, hard metals are hard and fragile. They are mainly made of the hard matrix. The metal matrix is held together by using the hard material. The hard metals are tough compared to hardened steel metals, alloys, and pure metals. In comparison to other metals, hard metals have higher temperature resistance. These are mostly used in producing cutting material such as cutters, drills, millings, etc. Moreover, hard metals are also used in the firming and punching tool. Titanium, chromium, steel, etc., are some examples of hard metals.

Titanium is lightweight and can alloy with vanadium to make a sturdy and corrosion-resistant material for making custom metal parts.

Titanium can use in pins, plates, and bone screws and is a biocompatible material. These specific features of titanium make it suitable for the high-performance vehicle manufacturing industry and aerospace.

These types of metals have specific characteristics and are not manufactured in the same ways.

Manufacturing of Metal Parts

Different methods are used to manufacture different metals. Different methods of manufacturing different metal parts have their capabilities and strength. Here, we will discuss different methods to manufacture different metal parts.

1- Extrusion- Pushing Metals into a Die

In this process, a heated metal is pushed into a die, and thus a tubular or an L-shape is created by the die. This method can use to structure the metals into complex shapes. Post finishing such as machining, drilling, cutting is required for the metal parts produced by the extrusion technique. The extrusion process requires constant cross-sections. The hot extrusion can make the larger metal parts with high complexity. On the other hand, the smaller metal parts with less complexity are manufactured by cold extrusion.

This technique works by a forced flow of a cylindrical bullet through a closed cavity. In the closed cavity, there is a die of the particular cross-section. These cross-sections profile the metal parts. The mechanical and the hydraulic press of the cross-sections force the metal parts to come out. As a result, the metal parts come out of the closed cavity in different shapes. The different operation types of the extrusion include friction, hot extrusion, and cold extrusion. The hot extrusion requires a high temperature to prevent the material from being hard, while the cold extrusion handles at room temperature to make the material stronger. In friction, the charge is pushed against the die by force.

Applications of the Extruded Metal Parts

The extruded metal parts have various applications. A smooth surface provides by the extrusion for the finishes and the paints. This property makes the extrusion best for the precision and cosmetics parts. This technique uses by the automotive and aerospace industries for its components. This method is also useful in other applications such as flooring, windows, railings, etc.

2- CNC Machining-Removing Material

It is a computer control manufacturing process. The raw material can be cut into desired shapes using the material removal process. In CNC machining, there are various kinds of machining operations. The kind of operation used depends upon the required surface texture and geometry. CNC milling and turning are the two main categories of this technique, and for industries, it is a go-to process.

There is a multi-point cutting tool in the milling machine. This milling process uses the rotatory cutter to get the required shape of the metal parts and remove the undesired material from the stock of the metals. The multi-axis rotation of the cutting tool is used for this purpose. Moreover, the undesired or extra metals can be removed by turning the single turning edge from the rotating workpiece in CNC. It results in the cylindrical structures in the parts of the metals.

Applications of CNC machined Metal Parts

The CNC machined parts have various applications. The CNC turned, and the milled metal parts are used by different industries worldwide. The CNC turned, and the milled metal parts are considered as the workhorses of the industries. Electronic, automotive, machinery, telecommunication, and electrical industries can produce various CNC custom parts and turning components. For example, Pins, gearboxes, heads, brushings, rods, and shafts can be created by using CNC turning. In the case of metal fabrication, CNC milling is also considered an ideal machining operation. CNC milling can be used for machining different medical components, aerospace structures, and car models.

3: Stamping- Cutting and Bending Parts

The stamping process forms the letters, images, and shapes on the sheet metals. Stamping is of two types, i.e.

- Mechanical Process

- Hydraulic presses

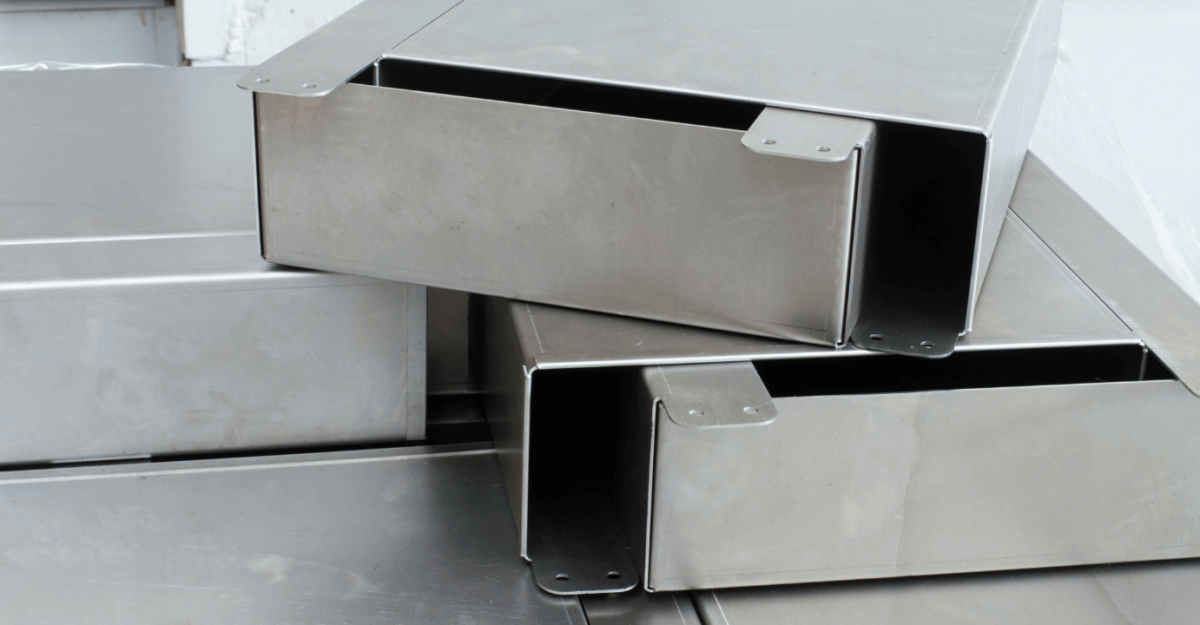

The metal sheets can be punched, cut, and bend into the desired forms by using this technique. The stamping process can mold metal sheets of various thicknesses into desired shapes and sizes. The four slide forming, blanking, and metal coining are included in the stamping operation. In case of high complexity and volume, this process is considered ideal with a very low cost of units.

In the process of sheet metal fabrication, stamping includes various techniques. These techniques include flanging, bending, coining, embossing, and jumping. This operation could be single-stage involving pressing the metal to produce the sheet with the desired shape to a multiple-stage operation. Normally, a sheet of cold metal is used in this process.

Applications of stamped metal parts

The stamped metals parts include various applications in industries. Each year, many different parts can be manufactured in different appliances, electronics, and automotive industries using the stamping process. The functional parts with high volume, such as brackets, chassis, and sheet metal enclosure, can be manufactured with the help of the stamping process. In the robotic industries, this process is considered an optimal option.

4: Forging-shaping the Metal

Forging is a process of manufacturing in which metals are given the desired shapes with the help of localized compression forces to provide the desired shapes to the metals. In other words, we can say that forging is the method of shaping and heating metals, and it is a famous automated industrial process. The range of the forgeable parts is from kilograms to hundred metric tons. Modern industries use high-impact forge machines to give the desired shapes to the metals. The forging process produces stronger metal components than the machining and casting. The forging process is economical, and less waste is produced at the end.

Forging is a simple process involving five steps. These five steps include:

- Heating

- Performing

- Forging

- Cooling

- Finishing

A great advantage of using this method is that there is no need for metal reduction of liquid during this process. It only requires the heating of the metal to a malleable state. The metal parts become stronger after heating to a malleable state.

Applications of Forged Metal Parts

The forged metal parts show various applications. The forged metal components are the basic need of industries throughout the world. The automotive industry uses these forged metal components for stress and shock applications. The shock and stress applications include balls, torsions, wheel spindles, shafts, and kingpins. These parts can use in a variety of tools and equipment. They are used in industrial equipment, surgical tools, domestic hardware, and electrical transmission.

5: Casting: Manufacturing Process

Casting is considered among the most flexible metal parts fabrication processes. It is best for a large variety of complex-shaped metal structures. Using this process, you can solve many metal fabrication problems less. During this process, the liquid material is poured into a mold. The mold is a prebuild hollow cavity having desired shape or structure. After pouring the liquid material into a mold, it is then allowed to cool down, and then it is solidified. Later, it is ejected from the mold to get the casted material part.

The casting method is of two types. These methods include Investment casting and Die Casting.

Investment Casting

In investment casting, the wax model of the final product is used. The ceramic can coat the wax. The wax is heated after the hardening of the ceramics. After heating the wax, it is drained out. The ceramic’s hardened shell becomes the mold for the desired metal part. Then the molten metal allows cooling after pouring into the mold. After cooling of molten metal, separate it from the mold. This process guarantees the production of complex and detailed parts. The investment casting method is only useful to meet the small production needs.

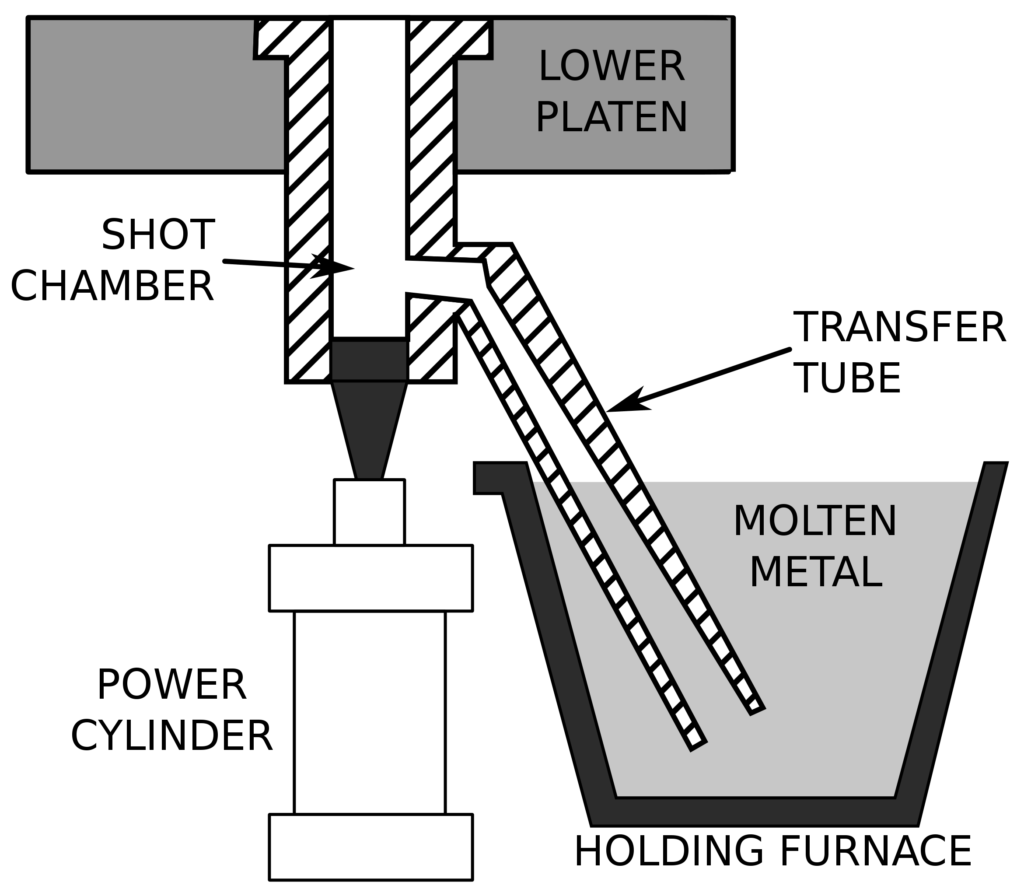

Die Casting

In this process, hydraulic pressure forces the liquid metal into a mold. The steel mold produces intricate shapes fabricated in the desired manner. The intricate shapes ensure sufficient accuracy and repeatability. It is ideal to meet the large production needs and small to medium-sized casting.

Applications of Casted metal parts

The casted metal parts have a lot of applications. One of the best applications is that almost all commercially manufactured mechanical devices can make by using this process. Moreover, in the case of production, CNC machining is outperformed on the cost by casting. The casting method regularly manufactures metal pipes, automobile components, and washing machines.

6: Metal Injection Molding: Large volume production process

The metal injection molding first involves the fine powdering of the metals. After the powdering of the metal, a feedstock is created by mixing it with a binder material. The resulting feedstock is then allowed to solidify. Once the feedstock is solidified, it is shaped into the final product. It considers the best technique for the production of a large volume. Moreover, it is not an expensive but a cheap method.

The main difference between metal injection molding and die casting is that the metal injection molding uses a feed of polymer-metal mix. The first stage involves the production of a mixture of polymer and metal. The second step involves melting and injecting the powder feedstock into the mold. After that, it is then allowed to cool and solidify to take the shape of the mold. The last step involves the ejection of the molded part from the mold. After ejection, clean it carefully.

Applications of Injection Molded Metal Parts

This process has various applications. Metal parts manufacturing is considered an innovative technology. By this process, many complex parts can produce with consistency. Moreover, in the automotive industry, a wide range of parts can produce by using this technique. A variety of medical equipment, airplanes, computers, ornaments, and fitting are manufactured using this manufacturing process. Moreover, this process is also used to manufacture the components of home appliances and office products.

7: Metal 3D Printing: Complex Geometries and Low Volume Parts

It is an effective method for producing metal parts by using laser technology. In the prototypes, it is the most commonly used method. This method is the best technique for the highly complex low volume parts with a short lead time and low cost. Moreover, the geometries and all-in-one assembly with inaccessible areas can produce by using this technique. Such production is almost impossible with standard tooling.

This process involves the step-by-step 3D printing of the metallic particles. In metal 3D printing, an inert gas such as argon is filled in the chamber where the operation is performed. The inert gas is filled to reduce the metal powder oxidation. After that, it is heated. After heating, a thin layer of the metal powder is spread over the build platform. The metal particles are fused as a laser scans the cross-section of the components, thus creating a layer. After creating the layer, the scanning of the whole area of the model is done. This way helps in building a fully solid part. You can manufacture the metal 3D printed part, and now you can use this metal part.

Application of 3D Printed Metal Parts

Like other methods, Metal 3D printing also has many applications. The process helps you to manufacture the various industrial parts quickly. This method is not expensive, so that you can manufacture the industrial parts at much less cost. It is an ideal process for the mass production of custom tools. Various specialized instruments having low volume can also be produced by this method. Thus this process is best for producing tools, spare parts, ductworks, fully functional prototypes, and rigid housing. Many dental ad surgical implants, decorative items, jewelry, and many other components can also produce in different industries by using the Metal 3D printing method.

Surface Finish Options for Metal Parts

In manufacturing operations, the surface finish of metal parts is the final process. The surface finishing provides the aesthetics and environmental protections to the fabricated metal parts. Moreover, some features that the machining operations cannot improve can be improved by this process. These features include corrosion resistance and surface roughness. In addition, the electrical and mechanical properties of the metal parts can also increase by using some treatments. Many options are used in the surface finishing of the metal parts. Some of the surface finishing options for the parts of metals are as follows:

- Electroless plating

- Vacuum plating

- Electroplating

- Anodic oxidation

- Chemical treatment

- Hot Dipping

- Thermal Spraying

- Painting

Conclusion

Metal is among the most used material in industries throughout the world. It is limited to the industries and considered a necessary material in household items. Metals provide us with a lot of the valuable equipment necessary for our daily lives. The equipment and tools made of metals have made our lives better and easier. We know metals possess highly unique and detailed characteristics.

In this article, we have discussed manufacturing the different parts of metals. The different fabrication options for the metal parts are also discussed. These manufacturing methods and fabrication options prove beneficial for manufacturing the desired metal parts. You can also grasp different methods of metal processing.