Whether we are talking about prototypes or final use products, accurate metal machining is a critical service. Without proper accuracy in metal parts, complex designs and assemblies become impossible. Modern-day CNC machining has alleviated most concerns regarding part accuracy. But there are still steps you can take to improve your accuracy further and take your metal machining to the next level.

This article breaks down the concept of Accurate Machining and discusses factors that lead to improved accuracy.

What is Accurate Machining?

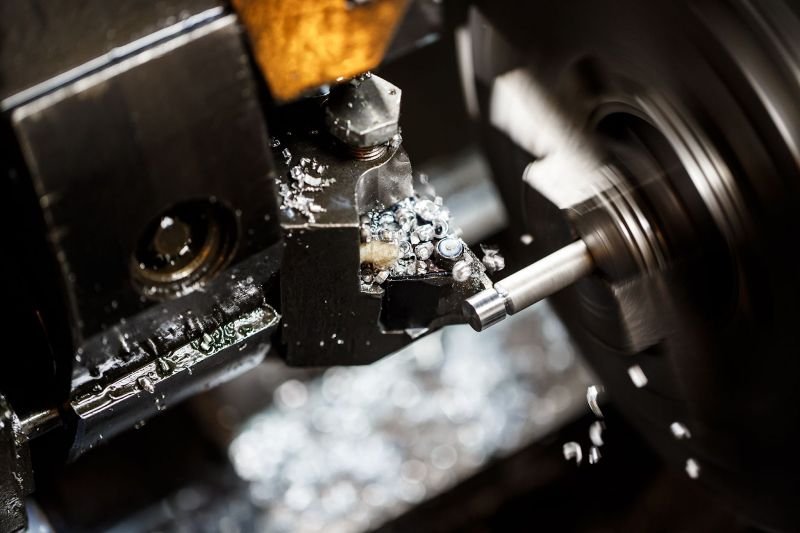

Machining accuracy is the measure of a machine’s ability to create parts as close to the final dimensions as possible. A high-accuracy machine is able to cut the workpiece according to the design dimensions with a negligible margin of error. CNC (computer-numerically controlled) machines are the only ones capable of such accurate machining.

Accuracy is an absolute necessity for metal machining. Most metal products are machined in parts and joined together using screws, clips, and welding. Any discrepancy in the part dimensions will result in a mismatch of joints during assembly.

You can grind and file away minor accuracy errors. But critical errors in accuracy will typically lead to major defects in the products. Defected products are often un-salvageable and end up discarded, resulting in loss of time and money.

What is Precision Machining?

Machining precision is the measure of a machine’s ability to create parts with the same level of accuracy repeatedly. A high-precision machine is able to create thousands of parts with the exact same design dimensions. Precision can also be seen as machining consistency and repeatability. Since CNC machines are computer operated, it is quite easy for them to cut parts with the same precision.

Precision is different from accuracy but is also directly related to accuracy. Most accurate CNC machines are also quite precise. If a machine is able to cut one part accurately according to design dimensions, then it will also be able to do the same for other parts.

A CNC machine with high precision but low accuracy is uncommon but not unheard of. These machines typically have a bad sensor resulting in poor calibration. Proper maintenance and cleaning of a CNC machine will reduce the chances of calibration errors.

Importance of Machining Tolerances for Accurate Machining?

Machining tolerances are the set of guidelines that dictate the margin of error in the cutting/machining of a metal part. Tolerances will tell the manufacturer how much deviation from the design dimensions is acceptable. These are usually defined as plus-minus a certain number and use the symbol “±.”

Design tolerances are different for different parts, and complex part designs require much tighter tolerances than simple part designs. For example, if you design a metal rod with a length of 1000mm and a diameter of 30mm, you can define the tolerances as ±1.0 mm for length and ±0.5 mm for the diameter.

Tolerance is also responsible for defining the accuracy of CNC machines. If a machine is able to match the dimensions within 0.1mm of the design, then it has a tolerance of ±0.1mm. Using a CNC lathe that has a cutting tolerance of ±0.1mm, you can machine the above-designed metal rod within its tolerances.

If a machine is able to stay within its rated tolerance while machining several parts, the process will be called precision machining.

Factors that Determine Accuracy in Machining

Machining is a complex science and a collective result of several engineering and design factors. Each of these factors has a significant impact on machining accuracy. Here is a breakdown of the most crucial accuracy factors of CNC Machining.

Machine Capabilities

Not all CNC machines are built equal. Higher-tier machines will have better accuracy, more versatility, and more features. 3-axis machines are the standard option for most manufacturers. But 5 and 6-axis machines bring another level of precision as you can fully machine a workpiece without removing it to change sides or orientation.

You can also look into different cutting machines like EDM, laser, water jet, etc. Each machine has its own advantages and tolerances.

Machine Maintenance

The simplest and easiest way to keep machining accurate is maintenance. Metal chips and coolant are an unavoidable part of machining. It would be best if you kept metal chips out of sensitive sections of the machine and properly cleaned any residual coolant.

Tool Quality

Cutting tools come in several shapes and are made of a wide range of materials. Ensure the use of correct tools for the correct workpiece materials. Hard materials can only be cut using harder tools. If you try to cut a titanium workpiece using an HSS tool, it will result in tool chipping. Tool chipping midway through machining can result in poor accuracy on some sections of the final part.

The following is a simple table comparing cutting tool materials according to Moh’s hardness scale.

| Tool Material | Material Hardness |

| Diamond | 10 |

| Ceramic | 9.5 |

| Silicon Carbide | 9.5 |

| Aluminum Oxide | 9.2 |

| Tungsten Carbide | 8.5 |

| High-Speed Steel (HSS) | 7 |

| Steel | 6.5 |

Metal Selection

A counter approach to tool quality is material selection. Instead of using expensive over-spec tools, you can use softer metals for your workpiece. Titanium and stainless steel are the hardest and toughest materials that one can use for metal machining. You can downgrade to aluminum or brass if you don’t need the utmost resilience.

The following table compares CNC-compatible materials according to hardness and yield strength.

| Metal | Description(Alloy or Temper) | Rockwell Hardness(B-Scale) | Yield Strength(MPa) |

| Aluminum | A93003-H14 | 20-25 | 145 |

| A93003-H34 | 35-40 | 200 | |

| Copper | ⅛ Cold Rolled | 10 | 221 |

| Commercial Bronze | ¼ Hard Rolled | 42 | 241 |

| Cartridge Bronze | ¼ Hard Rolled | 55 | 276 |

| Low Carbon Steel | Cold Rolled | 60 | 170 |

| Stainless Steel | Temper Pass | 88 | 207 |

| Cast Iron | As Cast | 86 | 344 |

| Titanium | Annealed | 80 | 255 |

Workpiece Holder

The workpiece needs to be properly clamped down to the bed of the CNC machine (chuck in the case of Lathe). If there is even a little wiggle room in the clamps, the workpiece will move under the pressure of the cutting tool resulting in misalignment and poor accuracy.

Probing System

A probing system is a series of measure probes that can be attached to a CNC mill. These probes press against the workpiece and accurately measure the dimensions. You can rely on a probing system to maintain accuracy during long machining runs.

You can use probing tools between tool changes and workpiece re-orientation. If the probes show dimensions within tolerances, you are right on track. Otherwise, you may need to re-adjust your machining operation.

Environment Control

Temperature and humidity can negatively impact the materials of a workpiece. Metals will contact in cold environments and expand in hot ones. Humidity can cause interference with the cutting tools and coolant effectiveness.

Calibration

Every machine under the sun will eventually drift from its ideal setting as time passes. Tools holders will become slightly loose, and the sensors on the CNC machine will degrade. But proper and regular calibration can bring your machine back to peak performance in no time.

Conclusion

Accuracy should never be taken for granted. It is a crucial element of metal machining, and without it, we would never have many of our favorite modern inventions. Accuracy is inherent to CNC machines, and by default, most machines will perform as intended. However, complex machining and tougher materials will eventually result in a loss in accuracy.

Before that happens, you must preemptively maintain and calibrate your machine. With just a few precautions, you can maintain machining accuracy and, in rare cases, increase it as well.

Why Choose QBH for your Metal Machining Needs?

QBH Technology is an expert in precise and accurate metal machining services. We offer several top-notch machining services, including CNC Turning, CNC Milling, and Sheet Metal Work. Additionally, QBH offers flexible MOQ and quick turnaround times for OEM manufacturing parts. If you need guidance with your technical drawings, you can rely on our expert engineers, who can help you refine and optimize your designs.

So don’t wait for another second and get started on your metal manufacturing with QBH. Contact us Now!