CNC machining is a flexible and customizable manufacturing process that is being used in several industries. But one industry that has received plenty of benefits from CNC machining is the smartphone industry. After all, smartphones are compact devices with several small components that require exceptional precision to manufacture.

In this article, we break down the key sections of smartphone design and how they benefit from CNC machining.

What is CNC Machining?

CNC is short for computer numerical control. CNC machining is the process of cutting off material from a solid chunk, called a workpiece. In this process, a microprocessor precisely and accurately moves the cutting tool. A CNC system can be attached to a number of machines for added precision.

CNC machining is a versatile process that has slowly but surely superseded the manual machining process. CNC machining is currently being used in several industries, including automotive, lighting, electronics, and of course, smartphones.

Types of CNC Machining

CNC machining can mean several things, as it is a group of processes. Any cutting machine that uses computer guidance to control the cutting tool is categorized as a CNC machine. The following are a few common examples of CNC-supported machines.

- CNC Turning (Lathe)

- CNC Milling

- CNC Routing

- CNC Laser Cutting

- CNC EDM

- CNC Plasma Cutting

- Multi-axis CNC Machines

- Etc.

Most CNC machines will use a variety of hard and sturdy cutting tools. High-speed steel (HSS) is a popular group of steel tools associated with CNC machining. But some machines rely on unconventional cutting tools to do the job.

Laser cutting machines use high-powered narrow laser beams to cut through the most robust materials. At the same time, EDM and plasma cutting machines use strong electric currents on conductive workpieces to chip away the material.

Benefits of CNC Machining in the Smartphone Industry

The humble smartphone is an insanely complex device with hundreds if not thousands of parts. As common with complex electronics, manufacturers often use several techniques to produce individual parts. Among those different techniques, CNC machining is the most common and popular manufacturing technique.

Here are a few key applications of CNC machining in smartphones and its benefits.

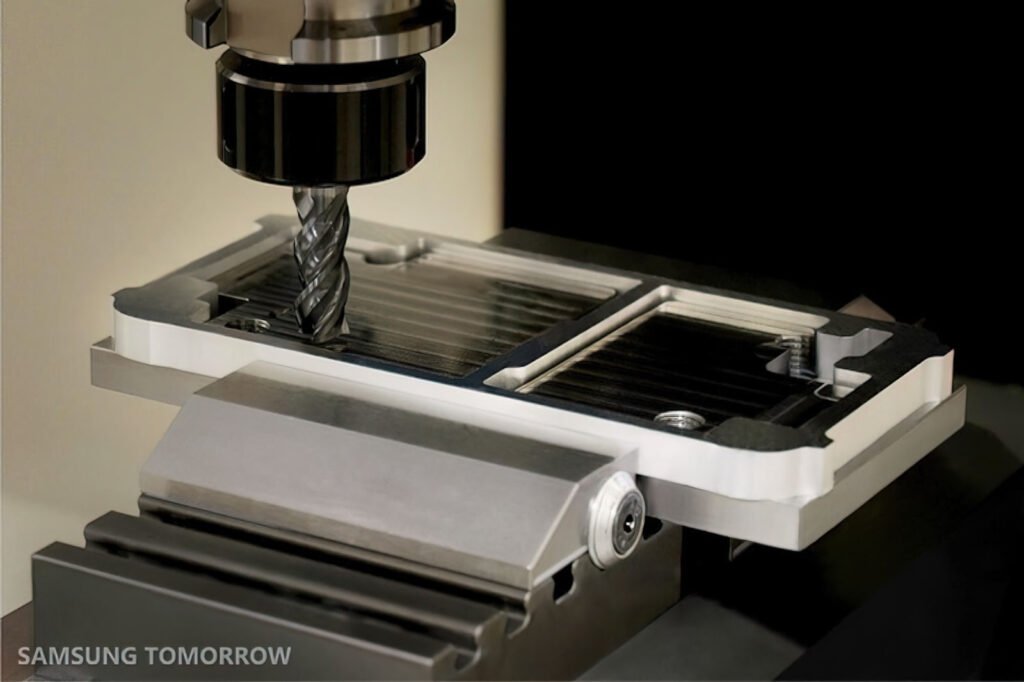

Frame Machining

Smartphone frames are the most obvious choice for CNC machining. They are dense and compact designs, with plenty of small channels, grooves, and holes. Though cheaper phones often use die-casting and metal stamping to save costs, medium to high-end phones can only be produced using CNC machining.

Material

Aluminum is the premier material for smartphone frames, but on rare occasions, smartphones have to be shipped with titanium or stainless steel frames. Aluminum is easy to machine and comes in several alloy varieties. Additionally, it is pretty accepting of finishes during post-processing.

Tolerances

Precision is a necessity for smartphones, even a millimeter worth of error can derail the entire production line. Luckily CNC machines have much tighter tolerances. CNC mills are typically used to machine out a smartphone frame and have a standard tolerance of ±0.005” (0.13mm). This level of precision allows modern-day smartphones to be incredibly thin and lightweight.

The standard thickness for a smartphone frame is under 8mm, and significant internal components range from 0.1mm to 0.5mm in size.

Design

From a design perspective, CNC is an ideal option for machining smartphones. The basic outline of the frame can be designed on CAD (computer-aided design) software. Afterward, the CAD file can be directly input into the CNC system.

Design operations like chamfering are always done using CNC machines. The CNC tool precisely moves around the edge of the smartphone and shapes it accordingly. Cavities are another essential part of a smartphone frame. The housing for the speaker, battery, haptic motors, and SOC (system on a chip) need high levels of precision, so the parts do not interfere with one another.

Cutouts for cameras, side buttons, and microphone holes are even more of a challenge. They are tiny and impossible to mill without a CNC system.

Small Components Manufacturing

Aside from the main frame of the smartphone, CNC is also used for various other tiny components. The power button, volume rockers, and sim tray all require high-precision machining. If the precision is slightly off and the buttons end up smaller than intended, they will rock around the frame. If the buttons are too big, they either won’t fit in the frame or end up being stuck and difficult to press.

CNC machining is also used to produce the components’ holding brackets and electrical shielding. Holding brackets are small, thin pieces of metal that secure the frame’s charging port, speakers, and camera assembly. Electrical shielding is flat metal pieces covering sensitive parts like the microprocessor to protect them from electrical interference.

Case Machining

CNC machining is a crucial part of case design and manufacturing. Smartphone cases require accurate dimensions for a nice snug fit. However, the smartphone will slide out of the case if the dimensions are too loose. While if the dimensions are too tight, you won’t be able to fit the phone inside it.

Templates

Phone manufacturers often ship out dummy units made out of solid aluminum to case manufacturers. These units have the same size and shape as the final product and are meant to be used as case templates.

Phone Cases

Phone cases are often manufactured using the injection molding process. It is an insanely cheap method of producing large volumes of the same product. But CNC is still predominant in the high-end case market. Leather cases are precision cut by CNC lasers and shaped to the body of a smartphone.

Additionally, some niche companies are offering wooded cases machined out of real natural wood.

Glass Machining

Touch-sensitive glass is now the norm for phone screens. As smartphones have grown in popularity, the demand for thinner and more precise glass tops has also increased. The glass top of a smartphone is a super-thin layer, coming in at under 3mm.

The problem with machining glass is precision, but about control. Glass is a brittle material, and when put in such a thin form factor, the risk of cracks increases exponentially. CNC machines slowly and carefully cut and shape the touch-sensitive glass with unparalleled precision.

Recently smartphone manufacturers have opted to use punch-hole cutouts or notched displays for their smartphones. Require additional precision, accuracy, and care while machining. An added challenge to glass machining is reducing the chances of scratches. Even if the glass doesn’t crack, scratches can render the entire product useless.

Customizations

CNC machining is at the very core of custom designs. And what better product to customize than your smartphone. Customizations for smartphones are typically reserved for phone backs.

Phone backs are flat metal, plastic, or glass sheets attached to the frame. The simplest method of customizing a phone back is engraving and etching. Manufacturers often use this process to add their logos or phone details on the back of the phone. You can use the same technique to engrave personal messages on phone backs for gifting purposes.

Another means of customization is a complete overhaul of the back design. You can add new design elements and cutouts for limited edition backplates for your smartphone.

Smartphone Accessories

Smartphones are now a central hub for several electronic accessories. Like phone cases, smartphone accessories like speaker docks or charging stations also require high levels of precision.

Some standard smartphone accessories that are made using CNC machines are as follows.

- Screen Protectors

- Battery Cases

- Stabilization Gimbals

- Additional Camera Lenses

- Additional IR or Thermal Cameras

- Phone Holders

- Car Mounting Accessories

- Etc.

Conclusion

Both smartphone and CNC machining are associated with cutting-edge technology and precision. So, it only makes sense that these two would go together hand in hand. We hope this article has shed some light on the several areas of smartphone manufacturing that benefit from CNC machining. Everything from tiny components to smartphone accessories is being produced using CNC machines.

Why Choose QBH for your Smartphone Manufacturing?

If you are in the market for precision CNC machining for your smartphone business, look no further than QBH Technology. Our precision CNC Turing and CNC Milling services are second to none. We also have several finishing and surface treatment options for your final parts.

So take advantage of our excellent OEM services and flexible MOQ by Contacting us Right Now.