Introduction

The manufacturing industry is fueled by engineers and designers that put part’s dimensions and geometric characteristics on a pedestal. Such a pragmatic approach to manufacturing significantly reduces the errors that could otherwise jeopardize the production process. Subsequently, CMM or Coordinate Measuring Machine was invented to facilitate highly accurate and precise production. It is an essential tool in the manufacturing process and enables the manufacturers to maintain the workflow. In this post, we will dive into the world of manufacturing to learn about CMM machines from inside and out. We will discuss the components, benefits, and challenges of using a CMM machine. So, let’s get started!

What is a CMM machine?

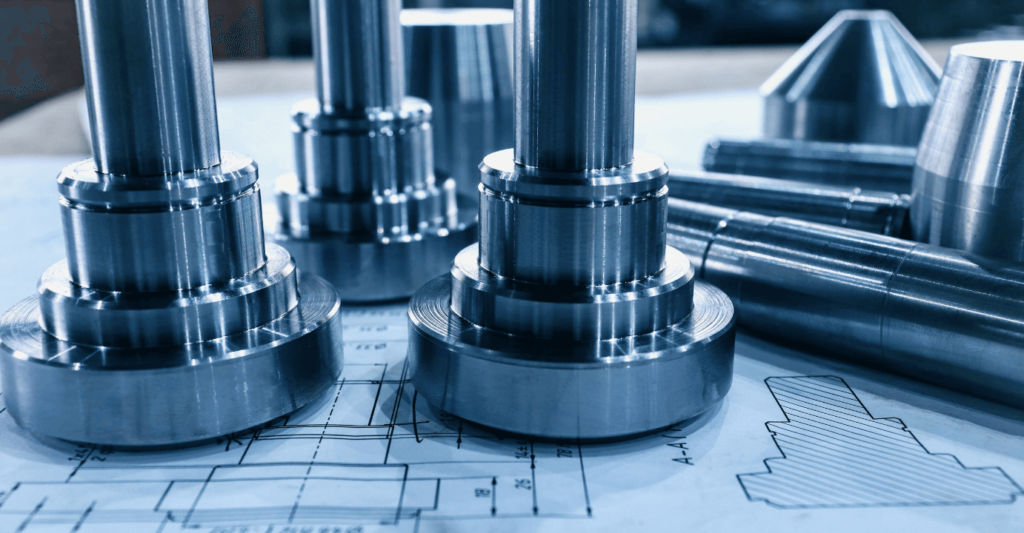

Creating prototypes and the final product requires pitch-perfect measurements. Accurate geometric and physical dimensions help run the manufacturing process flawlessly. However, there are two ways one can measure the physical dimensions of a product. Conventionally, people used hand tools or optical comparators to determine the dimensions. Such tools were prone to error as one needed excellent skills to operate them.

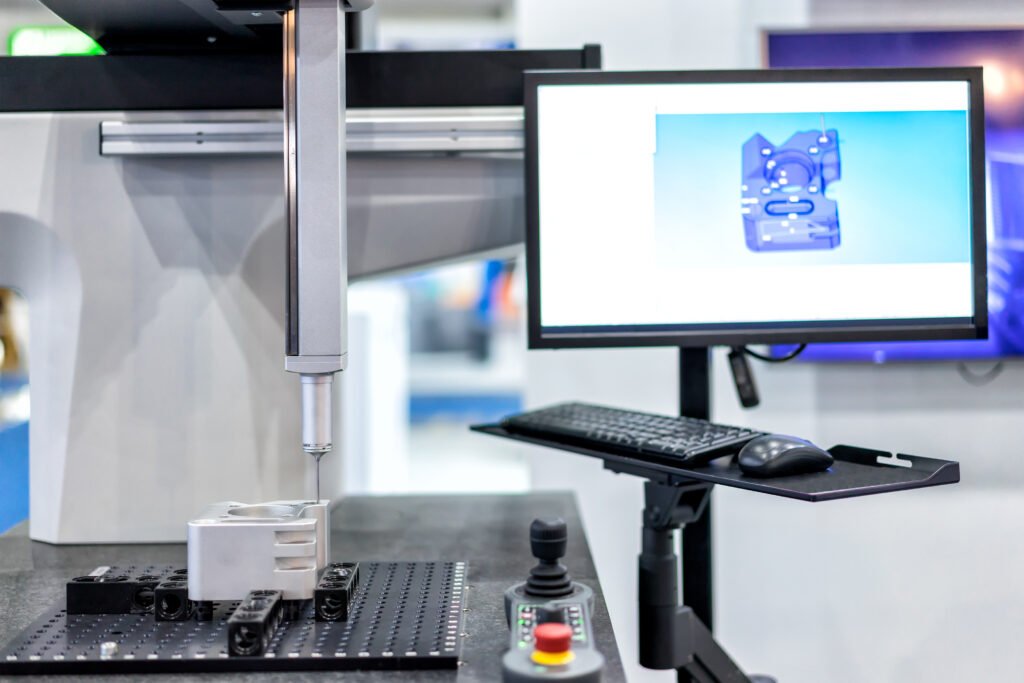

CMM or Coordinate Measuring Machine is a modern solution to determining accurate geometric physical dimensions without errors. The machine uses coordinate technology to measure the dimensions of a machine/tool part. The measurement includes the height, width, and depth of the part – recorded and measured in the X, Y, and Z-axis, respectively.

The very first three-axis CMM appeared in the early 60s. It was originally developed by Ferranti Company in Scotland in the 60s. The CMM used a 3D tracing device to develop 2-axis designs. It had a simple digital readout to measure precision components and was used primarily for military products. Here are some common types of modern-day CMM machines.

- Bridge CMM

- Gantry CMM

- Cantilever CMM

- Horizontal Arm CMM

- Measuring Arm CMM

- Optical CMM

But, do we really need CMM machines when traditional methods have done a fine job till now? Well, traditional methods have limitations that render them useless when it comes to developing more complex geometries. The speed and accuracy with which the CMM machines perform make it easier to produce precise parts and boost overall productivity.

What are the benefits of using a CMM machine?

How beneficial is a CMM machine for your manufacturing process? In this section, we will share five crucial advantages of using a CMM machine over traditional methods of measurement. Let’s discuss them.

1.Boosts productivity

Setting up a manufacturing process and running it efficiently is hard work. After all, it requires a lot of effort to design a manufacturing process that produces accurate results. However, errors in part measurement often lead to abruption – impacting the production significantly. With CMM, you can rely on technology to provide fool-proof measurement and run the manufacturing process relentlessly.

2.Quality assurance

CMM machines are reliable. The unmatched accuracy and precision in the machine allow engineers and manufacturers to measure and analyze the parts digitally. Not just that, a CMM machine can perform dimensional analysis, CAD comparison, reverse engineering, and tool certifications. Such features and facilities help with quality assurance.

3.Negligible operator intervention

The best thing about using a CMM machine is that it requires negligible operator intervention. The machine requires power and is entirely computer-controlled. Since the machine reduces the involvement of human personnel, the manufacturing process experiences significantly less operational error than traditional methods.

4.Increased compatibility

The Coordinate Measuring Machine has multiple probes and techniques. In other words, the machine is highly compatible with many types of tools, machine parts, and components. This makes the machine useful for measuring highly sophisticated geometries. A CMM machine will perform regardless of the complexity of the part.

5.Save time, money, and reputation

A CMM machine introduces the highest speed and accuracy to the manufacturing process. This makes the machine integral to the production flow. Simultaneously, the machine helps manufacture complex tools easily, saving money and time. The increasing use of a CMM machine in the manufacturing industry has helped reduce the time and money required for rampant production. Most importantly, speed and accuracy have allowed companies to raise their standards and reputation.

How does a CMM machine work?

A Coordinate Measuring Machine works in two ways. First, you can use touch probes and measure the tools/parts through a contact mechanism. Secondly, you can use cameras, sensors, and lasers to accomplish an error-free measurement. Let’s dive deeper to understand how a CMM machine functions. Here are the different components used in a CMM machine. Understanding how these components function will give you a firm grasp of the machine’s functioning.

1.Probe

Probes or touch probes are crucial to the machine’s functioning. It is responsible for the measuring action. Probes are present on CMM machines that don’t use optical light, cameras, lasers, and other sensors for part measurement. The tip of the probe is made from a rigid and stable material. The strong tip is temperature resistant as it is made from ruby and zirconia. The tip is usually spherical in shape or needle-like.

2.Granite Table

The granite table in a CMM machine adds strength to the machine. The table is very stable and is not affected by fluctuations in temperature. It is crucial to the machine’s functioning as it reduces wear and tear. Since the table’s shape remains the same, the machine provides highly accurate measurements.

3.Fixtures

Fixtures in a CMM machine add stability and support during the manufacturing process. These help keep the parts in place. Fixing the parts is critical to achieving accurate measurements. The CMM machine has other fixing tools like fixture plates, clamps, and magnets.

4.Air Compressors/Dryers

Air compressors and dryers are quite commonly found in Coordinate Measuring Machines. These are staples in CMM machines like the standard bridge or gantry-type machines.

5.Software

Lastly, the CMM machine operates on software. Although it is not a physical component, one should not compromise the program’s quality used on the machine. The software helps the machine analyze the probes and other sensored components.

Let’s assume we have to measure a part through the Coordinate Measuring Machine. We need to place the part on the CMM’s base to do that. The base of CMM is made of granite, which is a dense material. It provides stability and rigidity to the machine. As a result, the machine eliminates all external forces and provides an accurate measurement.

The machine also has a movable gantry that houses a touching probe. The computerized CMM machine controls the gantry and moves the probe along the X, Y, and Z-axis. The movements in the three directions help the machine replicate every facet of the part placed on the CMM’s base.

How does the probe function? As we mentioned earlier, the touching probe comes in contact with the part. Once in contact, the probe sends an electrical signal to the computer. It touches many points before the computer maps out the part. The next stage in the measurement process is analysis.

The computer has adequate data captured through the probe. To be precise, the computer has the part’s X, Y, and Z coordinates. The data is processed and analyzed to construct the part’s physical features. The measuring mechanism is similar for Coordinate Measuring Machines equipped with cameras, lasers, or other systems.

What are the challenges of using a CMM?

But, what are the limitations of a CMM machine? With the advantages of using a CMM machine come the following drawbacks. We suggest you consider these drawbacks as challenges and focus on overcoming them.

1.Measuring fragile parts

The CMM machine requires the probe to touch the surface of the part to be measured. This makes it challenging to measure parts that are not very durable. The probe will have to consecutively touch the surface of the part, which can lead to deterioration of the material finish.

2.Probe selection

One should only work with the right probe. You should be careful with probe selection since measuring different parts requires different probes. We suggest you determine the part’s physical structure, the required design, and the probe’s ability when selecting the suitable probe.

3.Physical contact with parts

Are you measuring parts made from soft materials? Parts made out of rubbers and elastomers might lose their form due to the probe coming in contact with them. The physical contact will lead to errors that you will realize during digital analysis.

Keep reading!

There you have it. Measuring a part’s physical and geometric properties during manufacturing has never been easier. With a CMM machine, you now have the power to make highly informed decisions, boost productivity, and reduce errors across the manufacturing process. We went through the basics, advantages, limitations, and working of a CMM machine in this extensive guide.

Although now you have an adequate understanding of how CMMs work, we suggest you consider consulting manufacturing experts. Most modern manufacturing service centers provide a combination of part’s dimensional analysis and several manufacturing procedures like machining, molding, 3D printing, and more. Did you find this guide helpful? Let us know in the comments. Also, don’t forget to check out other informative posts on the blog.