Prototyping is a huge part of medical research and development. While general-purpose prototypes can be manufactured using any number of materials, medical devices are limited to biocompatible materials. Choosing the suitable materials for your medical prototypes can be a challenging endeavor.

So here is a detailed guide on material selection for medical prototypes.

What is Biocompatibility?

The biocompatibility of a material is its ability to exist in harmony with living tissue. The material must not degrade upon interaction with the tissue or damage the tissue. Biocompatible materials are often used for medical implants, like knee replacements.

Biocompatible materials can be both metallic and non-metallic in nature. However, materials must pass a biocompatibility test to get a biocompatibility certification. ISO (International Organization for Standardization) is responsible for a majority of global biocompatibility certifications.

Different Biocompatible Materials

Any material that passes the biocompatibility test is safe to use for internal medical implants. Here are some common biocompatible materials used for medical prototypes.

Metal

- Titanium

- Stainless Steel

Non-Metal

- PC (polycarbonate)

- PEEK (polyetheretherketone)

- PEI (polyetherimide)

- PPSU (polyphenylsulfone)

- Acetal

- Nylon

Liquid

- ABS-Like Resin

- Silicone Rubber

Manufacturing Medical Prototypes

The fabrication of medical prototypes is primarily dependent on material choice. Some materials are very restrictive and only compatible with one type of manufacturing process.

Here are some of the most commonly used manufacturing processes for medical prototypes.

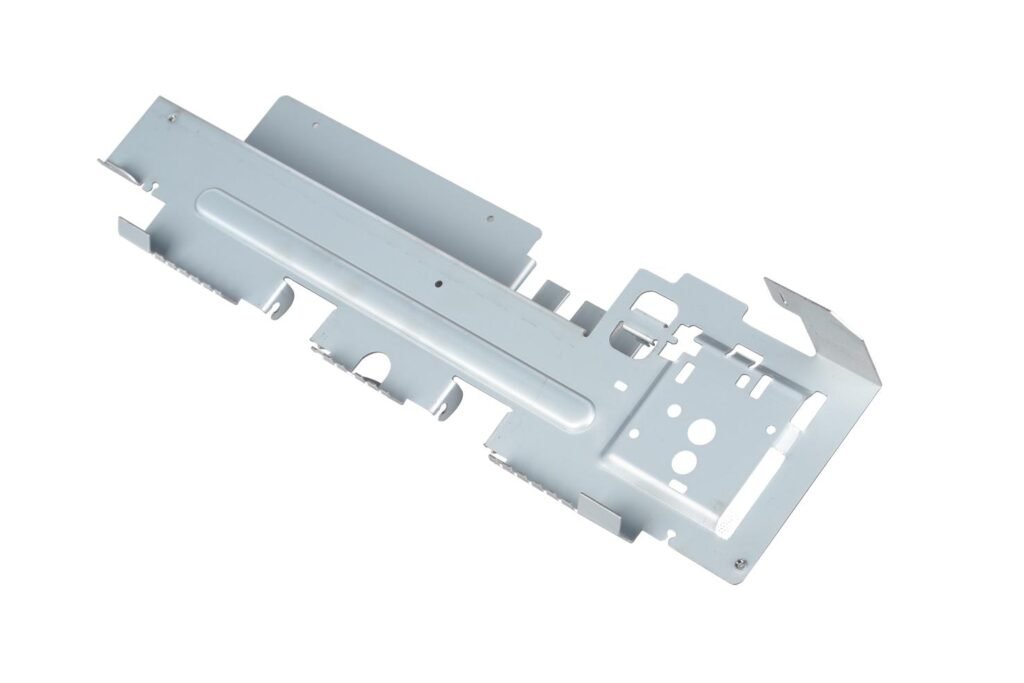

1.CNC Machining Medical Prototypes

CNC machining is an incredibly versatile and flexible prototype manufacturing method. It has near-universal compatibility with all sorts of metal and plastic materials. CNC allows for quick and precise machining of prototypes. However, different materials come with their own compromises.

Plastic Materials

Plastics like PEEK, PC, Nylon, etc., are generally well regarded for medical prototypes. They are ideal for the prototyping phase, due to their lower cost and lighter weight. Additionally, they are creep and temperature resistant, resulting in easy sterilization.

Metal Materials

Metals are considered premium materials for medical implants but are poor choices for prototyping. Titanium is a highly resilient metal and won’t degrade or react with body tissue. Stainless steel is a low-cost alternative to titanium and is particularly favored for medical equipment and surgical instruments.

Titanium is an expensive raw material that requires expensive tooling and machining to work. This is no issue for final medical implants, but prototypes typically undergo several iterations and changes. So the prototyping costs can add up quickly.

2.Injection Molding Medical Prototypes

Injection molding is a quick and reliable method suitable for large-volume productions. Ideally, you should not use this method for prototyping, as the tooling costs for the molds are incredibly high. Standard prototyping practice dictates you use CNC or 3D printing for your early prototypes and only use injection molding for the final prototype before commercial production.

Plastic Materials

Injection molding is pretty much incompatible with metallic materials, with only a few exceptions. Plastics like PC, PEEK, PEI, and PPSU are commonly used for medical prototypes. Injection-molded plastics are used for mass production parts, while CNC machining is used for patient-specific parts.

Liquid Silicone

Silicone rubber is often used to overcoat rigid plastic medical implants with a softer material. You will commonly see liquid silicone-coated parts in external medical devices, like prosthetics.

An alternative method for liquid silicone coating is vacuum sealing.

3.3D Printing Medical Prototypes

3D Printing is an additive manufacturing technique that can encompass several manufacturing sub-categories. 3D printing is a slower manufacturing process but more versatile than CNC machining.

For medical prototypes, there are only a couple of viable 3D printing processes.

Plastic 3D Printing – FDM

FDM (Fused Deposition Modeling) uses molten plastic extruded through a nozzle to create intricate and complex shapes. Nylon is the only commercially used biocompatible material that is also compatible with FDM.

Metal 3D Printing – SLS

SLS (Selective Laser Sintering) uses a high-powered precisely-controlled laser to selectively sinter (melt) metal powder to create the desired shape. Metal 3D printing is the most expensive manufacturing technique for medical prototyping.

Titanium is currently the only real choice for this method of medical prototyping.

Resin 3D Printing – SLA

SLA (Stereolithography) uses a high-powered precisely-controlled laser to cure (harden) photosensitive resin. This is a very rare method of medical prototyping as it is expensive and very limited in material choices.

Sterilization of Medical Prototypes

Medical equipment is generally non-reactive and safe to use. But over time, germs and microbes will accumulate on the surface. So it is necessary that medical equipment be sterilized before use. Here are some standard sterilization methods for your medical prototypes.

- Gamma Irradiation (GI)

- Autoclave (AC)

- Dry Heat (DH)

- Ethylene Oxide (EtO)

- Oxygen Plasma (OP)

- Ultraviolet (UV)

- Chemical Sterilization (CS)

Cost of Medical Prototypes

Prototyping medical parts is an expensive endeavor. However, some methods are more expensive than others.

Manufacturing Costs

CNC is the most cost-effective method for prototyping. 3D Printing, on the other hand, is excellent for rapid prototyping but can be more expensive than CNC. Injection molding is not recommended for prototyping and is better suited to mass production.

Material Costs

Metals are obviously the more costly option for prototyping. But CNC machined metal prototypes will be cheaper than 3D printed metal prototypes.

Conclusion

Selecting the right materials for your medical prototypes might seem daunting. However, once you have a good grasp of the process details, it becomes much more manageable. Consider both the manufacturing process and cost impact when selecting the best material option. Some materials are locked into specific manufacturing processes, adding unintended costs to your prototyping phase.

For experienced and skilled prototype manufacturing, look no further than QBH Technology. We offer a diverse range of machining services for the medical industry. Our CNC Machining and Quality Assurance are second to none. As a bonus, we have low MOQ and quick turnaround times.

Don’t miss out on your excellent prototyping services, and Contact us Now!