Introduction

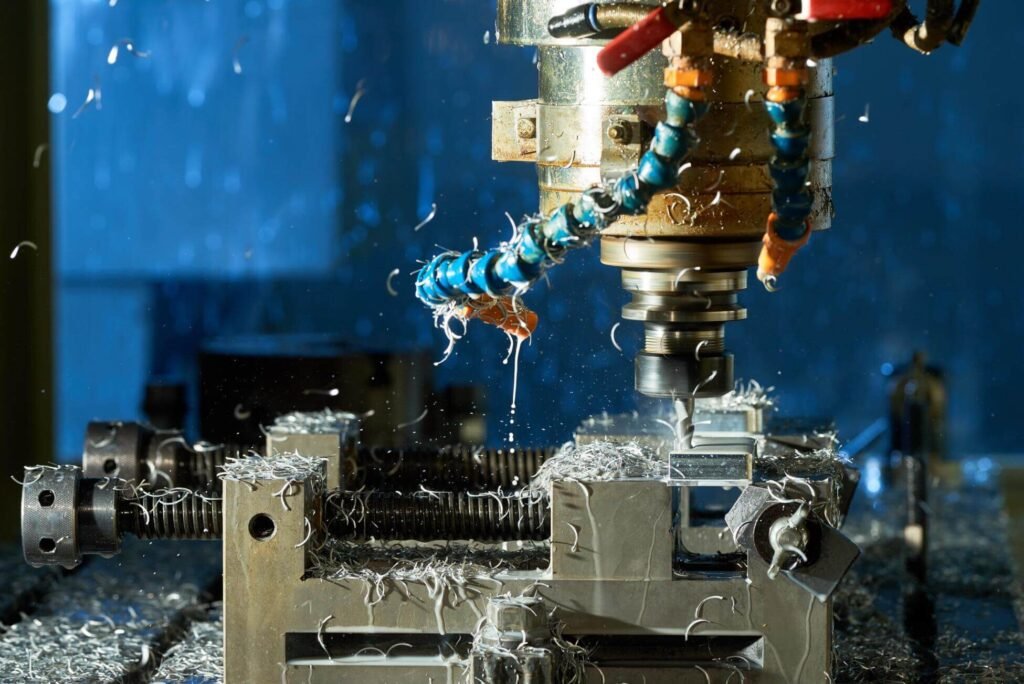

Why is the aerospace industry different from other industries we have covered on our blog? Is it the cost, or is it what’s at stake? The aerospace industry cannot afford the consequences of part failure. This is because human lives are at stake. Every part should work in harmony with the other, which puts immense pressure on the design and manufacturing process. We have found CNC machining an ideal manufacturing process for the aerospace industry since it delivers the required precision and tight tolerances while prioritizing quality and time. However, there are several challenges associated with CNC machining, especially for manufacturing aerospace parts. Let’s discuss them in detail!

1.Finding suitable manufacturers

Aerospace engineers and manufacturers often find it challenging to source manufacturers, especially reliable ones. Finding the right manufacturing partner helps meet the special requirements in the aerospace industry. The manufacturing company and supplier should have AS9100 certification based on ISO 9001 since quality and safety are everything to the aerospace industry.

The challenge is to find manufacturers with such certification as AS9100 is expensive and takes the manufacturer quite some time to earn it. We suggest you go for a digital manufacturing company as they have a wide pool of certified manufacturing partners that can supply the necessary material.

2.Achieving required material properties

Aerospace components manufacturing comes with highly specific material properties. Although the metals are usually heat-treated to trigger the desired amount of hardness and strength, the heat-treating process poses many challenges. Once heat treated, the metal becomes harder and stronger – perfect combination to achieve tighter tolerances

However, CNC machining such hardened material is expensive, time-consuming, and wears out the tools quickly. The metal can be heat treated after machining as well. But that comes with a whole new set of issues. Heat treating after machining can affect the part’s dimensions and push it out of spec.

3.Dealing with CNC limitations

Aircraft are made of millions of small and large components assembled to perfection. The size of the parts can be an issue while machining. Since typical CNC machining beds are only a few feet long, they might not support larger structural aerospace components.

In other words, you will have to work hard to find CNC machine suppliers that can work on bigger components. You can also redesign the large part to make things manageable. However, that will increase the aircraft’s overall weight due to the additional fasteners and holding materials.

4.Deformation due to residual stresses

Components like aircraft engines or compressor housing are made out of a large block of material. Such components have large internal cavities and can take a lot of time and effort to manufacture. Not just that, the process ends with a lot of scrap material and residual stresses in the component leading to deformation.

Engineers and manufacturers often rely on the Internal and External Removed Material Ratio to determine how much material they will need to remove. You can even cast such components instead of machining them.

Casting helps overcome material wastage and warping. However, you will have to rely on CNC machining to finish the component while meeting the set tight tolerances.

5.Achieving complex geometries

Some aerospace components require complex geometries since they need to fit into tight spaces, reduce weight, and maximize overall strength. Such complex geometries are hard to achieve using CNC machining.

Although such complex geometries in the aerospace industry are often unavoidable, one should check if the geometries are necessary or not.

We suggest you promote design for manufacturability among your team of designers and engineers. DFM considers the feasibility, time, and design costs while addressing the component’s complexities.

6.Efficient sourcing of suitable materials

CNC machining isn’t possible if you don’t have the material ready. Finding or sourcing suitable materials for the components can be a nightmare. You will often find yourself searching for superalloys and specialized plastics like titanium, nickel alloys, Ultem, and more.

Such materials are required constantly, which makes sourcing them a long-lasting challenge. Again, a digital manufacturing ecosystem will help you search for reliable suppliers. This allows the engineers and designers to focus on their tasks instead of worrying about logistics.

7.Dealing with advanced engineering plastics

Most aircraft use advanced engineering plastics that are quite challenging to machine. Such plastics are high temperature resistant and possess high tensile strength. Advanced engineering plastics function more like a metal than a polymer and can quickly dull the cutting blades.

Consequently, the CNC machines will lose their accuracy and precision due to improper cutting speeds. It is crucial for you to have highly skilled engineers and machinists in your team. You will need to optimize the cutting speeds and machine the AEPs under ideal conditions.

8.Lack of demand/production

Lastly, demand for aerospace parts and components is constantly fluctuating. The demand for some components could go from non-existent to overwhelmingly large in a matter of hours. Since aerospace components are not mass-produced, you often find yourself in a high mix, low quantity production scenario.

It involves reviewing and setting up manufacturing processes to produce each component. This can be time-consuming and often quite expensive since the manufacturing partners have to work on complex geometries. Such projects are not efficient and cost-effective.

Keep reading!

Running into the challenges mentioned above is guaranteed, especially when you work as an engineer or manufacturer in the aerospace industry. Although such challenges are prevalent in other industries, the inability to overcome them can lead to scary consequences in the aerospace sector. We suggest you make the most of the lessons provided in the post and put them to use when you run into similar CNC machining issues. Did you find this post helpful? Let us know in the comments. Also, don’t forget to check out other informative posts on the blog!

Related Articles: